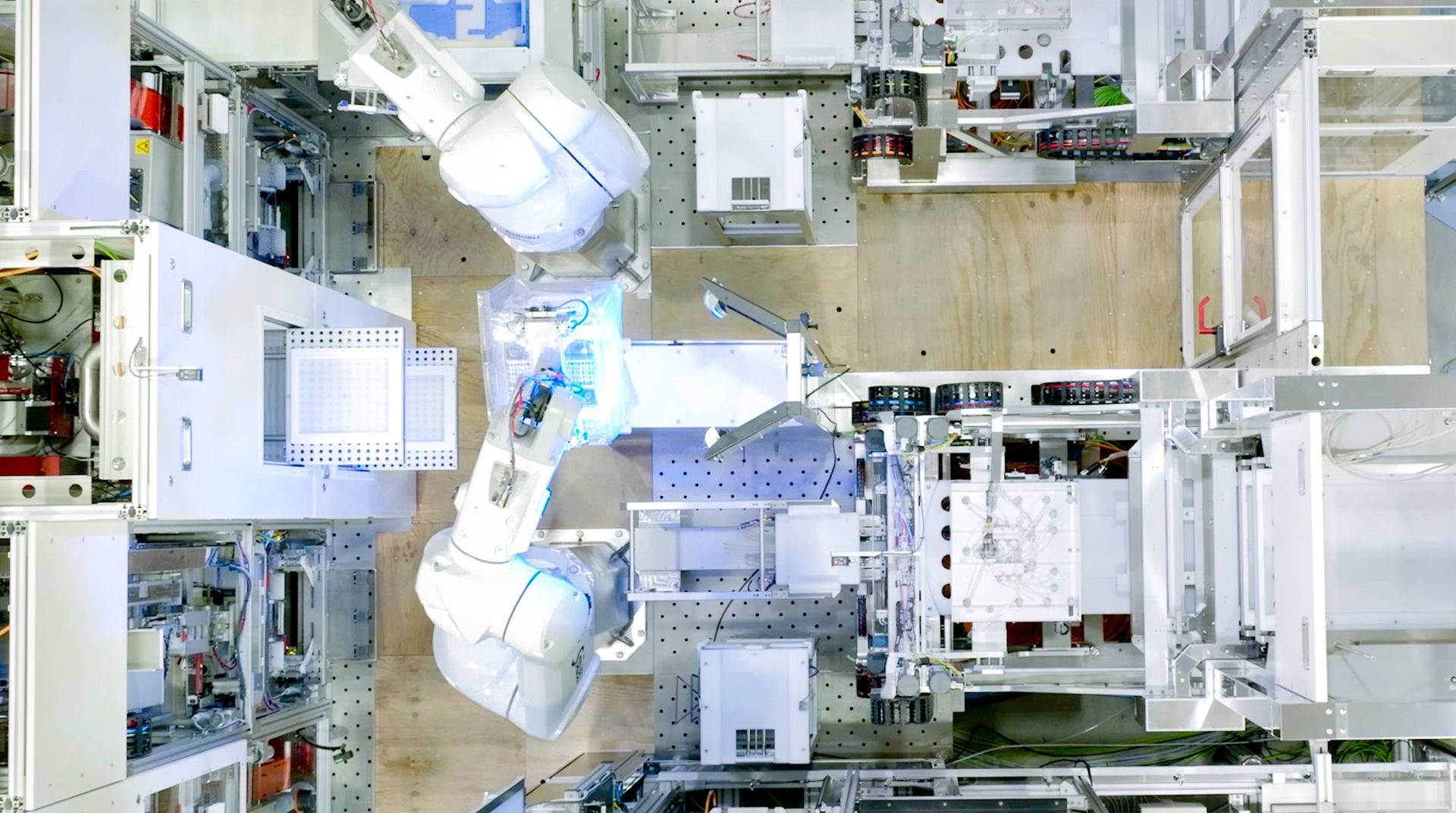

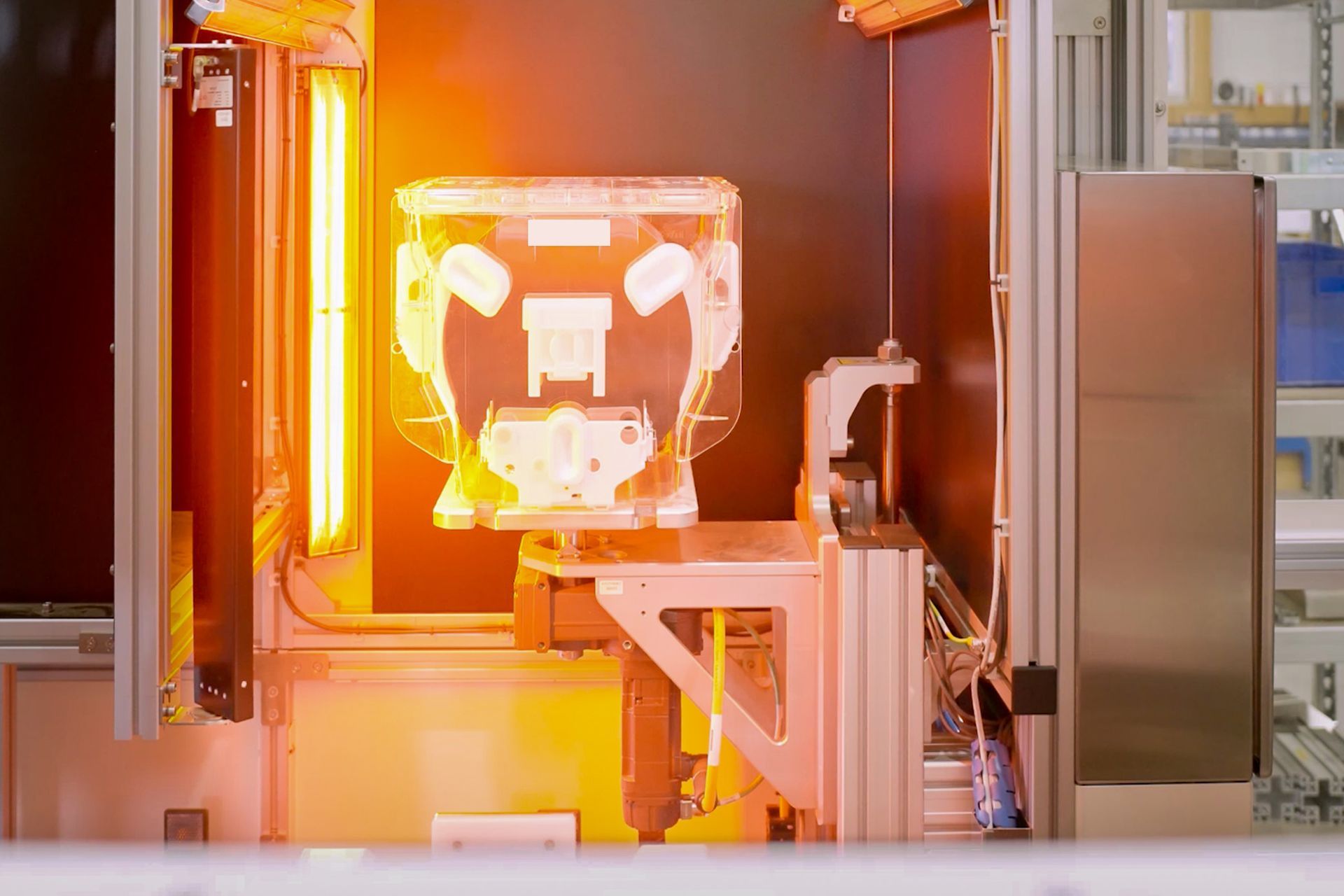

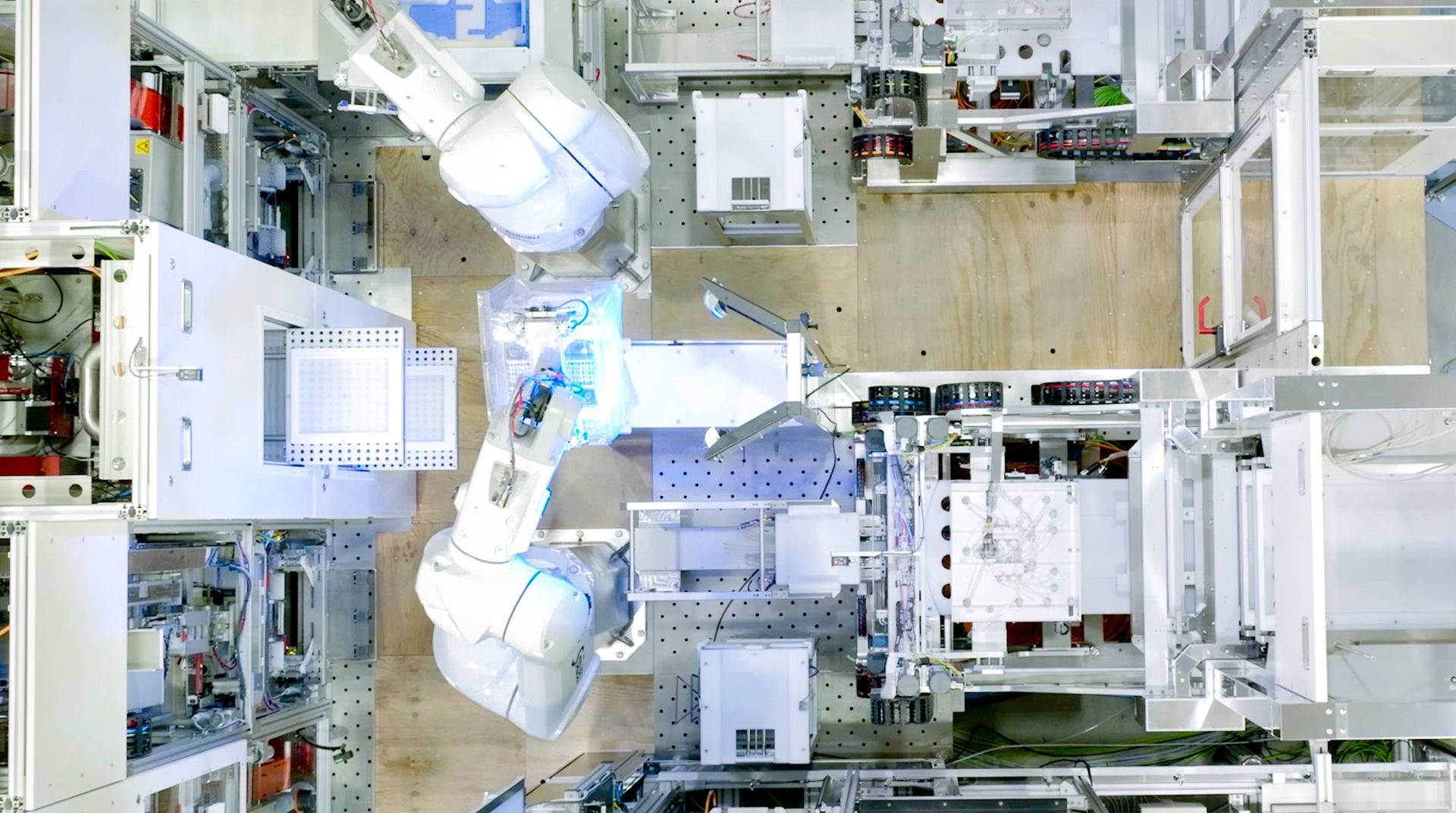

FOSB & FOUP Packaging System for Your Semiconductor Fab

In semiconductor production, packaging determines the integrity of your wafers. ABT fully automates this critical process step - for reproducible quality, traceability and packaging that meets your production standards.

Whether FOSBs, FOUPs or other carriers such as wafer boxes, SFS, HWS - the ABT system is flexibly adaptable and offers safe, validated handling even with increasing throughput and cleanroom requirements.

The compact design, combined with precise inspection and labeling technology, makes ABT a future-proof solution for modern packaging processes.

FOSB & FOUP Packaging System for Your Semiconductor Fab

In semiconductor production, packaging determines the integrity of your wafers. ABT fully automates this critical process step - for reproducible quality, traceability and packaging that meets your production standards.

Whether FOSBs, FOUPs or other carriers such as wafer boxes, SFS, HWS - the ABT system is flexibly adaptable and offers safe, validated handling even with increasing throughput and cleanroom requirements.

The compact design, combined with precise inspection and labeling technology, makes ABT a future-proof solution for modern packaging processes.

100% leak test of the weld seam of the packaging

Minimum cycle times for at least 300 FOSBs / day

Precise quality controls, including cross-slot checks

Synchronization to host systems through SECS / GEM

100% airtight & clean

100% leak test of the weld seam of the packaging

Higher throughput

Minimum cycle times for at least 300 FOSBs / day

Clean room compliance

Precise quality controls, including cross-slot checks

Maximum traceability

Synchronization to host systems through SECS / GEM

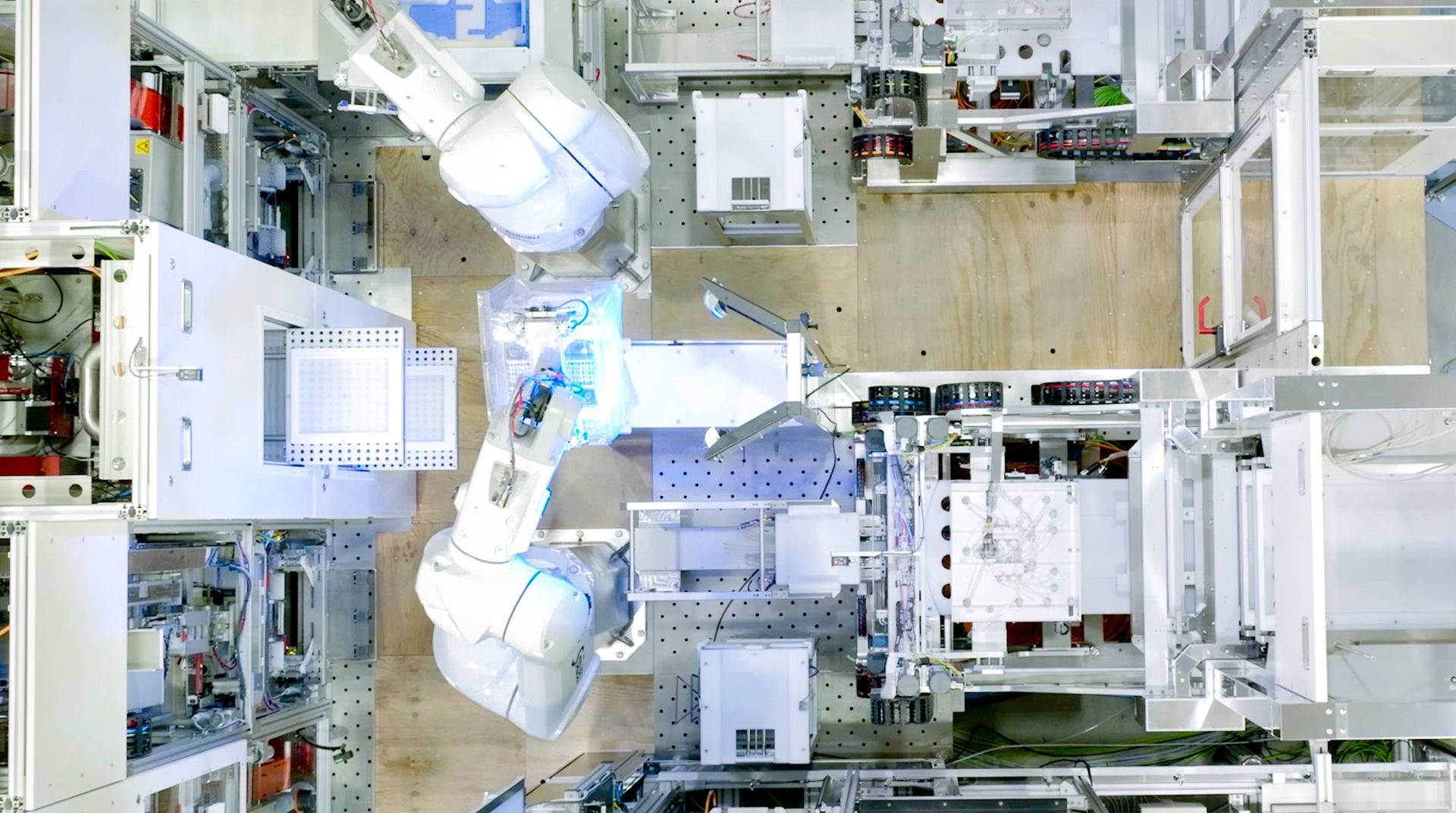

FOSB & FOUP Packaging System for Your Semiconductor Fab

In semiconductor production, packaging determines the integrity of your wafers. ABT fully automates this critical process step - for reproducible quality, traceability and packaging that meets your production standards.

Whether FOSBs, FOUPs or other carriers such as wafer boxes, SFS, HWS - the ABT system is flexibly adaptable and offers safe, validated handling even with increasing throughput and cleanroom requirements.

The compact design, combined with precise inspection and labeling technology, makes ABT a future-proof solution for modern packaging processes.

100% airtight & clean

100% leak test of the weld seam of the packaging

Higher throughput

Minimum cycle times for at least 300 FOSBs / day

Cleanroom compliance

Precise quality controls, including cross-slot checks

Maximum traceability

Synchronization to host systems through SECS / GEM

FOUP & FOSB packing: step by step to automated perfection

FOUP & FOSB packing: step by step to automated perfection

Step 1: Identification & Slot Verification

Every container correctly identified and assigned

FOSBs and FOUPs are clearly identified by RFID. Thanks to integrated cross-slot checks, the system automatically detects incorrect assignments or slot overlaps. This helps you to avoid misallocations and protect your process stability.

Functions:

• RFID-based identification

• Cross-slot verification for secure slot assignment

• Data synchronization with host systems

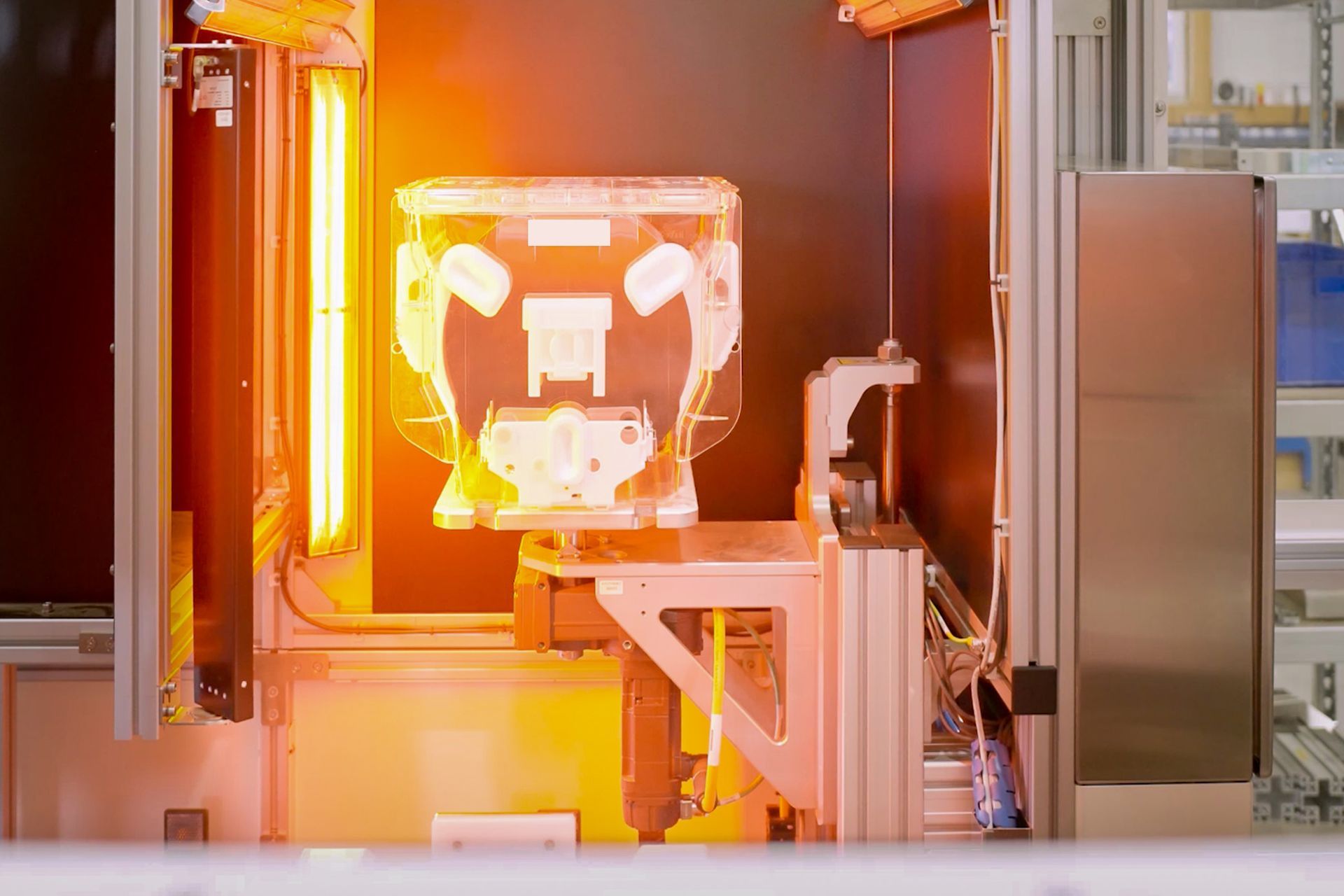

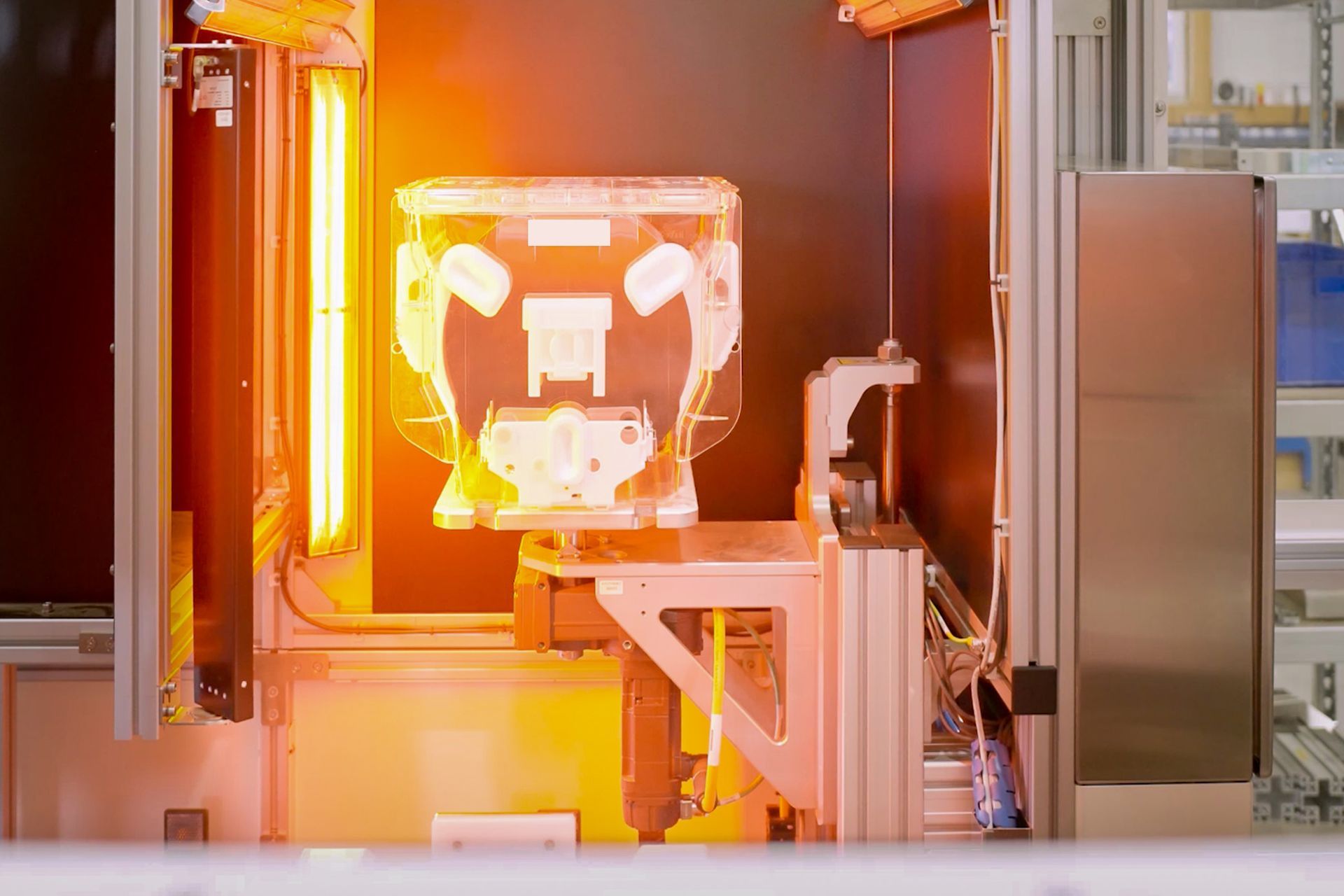

Step 2: Leak test and inspection

100% tested – for maximum product safety

Each packaging unit is tested for leaks before the next step. Leaks are detected and sorted out – automatically and documented. This ensures particle protection and meets the requirements for controlled environments.

Functions:

• Automated leak testing

• Testing against product-specific limit values

• Digital test protocols for each handling

Step 3: Labeling & traceability

Serial number, status, batch information – automatically labeled

All packaging units receive a tamper-proof label with a serial number, timestamp and inspection result. The information is stored digitally and is available for MES, ERP or auditing.

Functions:

• Automatic labeling with serial and batch number

• Tracking of container movements via SECS/GEM

• Compliant with cleanroom requirements

Step 4: Packaging & delivery

Standardized, hygienic, automated

After passing the test, the unit is double-packed. It is transferred to downstream processes - whether manually, via AMR or fully integrated into an existing line. Everything is documented without interruption. All required information can be passed on to downstream systems (handshake principle).

Functions:

• Cleanroom-compatible protective packaging

• Compatible with AMR/OHT systems

• > 300 FOSBs/FOUPs per day

Step 1: Identification & Slot Verification

Every container correctly identified and assigned

FOSBs and FOUPs are clearly identified by RFID. Thanks to integrated cross-slot checks, the system automatically detects incorrect assignments or slot overlaps. This helps you to avoid misallocations and protect your process stability.

Functions:

• RFID-based identification

• Cross-slot verification for secure slot assignment

• Data synchronization with host systems

Step 2: Leak test and inspection

100% tested – for maximum product safety

Each packaging unit is tested for leaks before the next step. Leaks are detected and sorted out – automatically and documented. This ensures particle protection and meets the requirements for controlled environments.

Functions:

• Automated leak testing

• Testing against product-specific limit values

• Digital test protocols for each handling

Step 3: Labeling & traceability

Serial number, status, batch information – automatically labeled

All packaging units receive a tamper-proof label with a serial number, timestamp and inspection result. The information is stored digitally and is available for MES, ERP or auditing.

Functions:

• Automatic labeling with serial and batch number

• Tracking of container movements via SECS/GEM

• Compliant with cleanroom requirements

Step 4: Packaging & delivery

Standardized, hygienic, automated

After passing the test, the unit is double-packed. It is transferred to downstream processes - whether manually, via AMR or fully integrated into an existing line. Everything is documented without interruption. All required information can be passed on to downstream systems (handshake principle).

Functions:

• Cleanroom-compatible protective packaging

• Compatible with AMR/OHT systems

• > 300 FOSBs/FOUPs per day

Integration & system transparency

From stand-alone solution to integrated production cell

In many production environments, packaging and testing are still run in isolation – often manually and without a direct connection to traceability systems.

The ABT system closes this gap: it communicates directly with your host system via SECS/GEM and automatically transmits all test results, labeling data and container IDs. This creates an integrated, documented packaging cell – without any additional work for your team.

Remote image and video monitoring relieves the operator and ensures maximum traceability of each lot.

ABT can be immediately synchronized with existing host systems

Relief for operators through remote image and video surveillance

100% traceable batches for each FOSB including data recording

Adaptation to production-specific requirements

Step 4: Packaging & delivery

Standardized, hygienic, automated

After passing the test, the unit is double-packed. It is transferred to downstream processes - whether manually, via AMR or fully integrated into an existing line. Everything is documented without interruption. All required information can be passed on to downstream systems (handshake principle).

Functions:

• Cleanroom-compatible protective packaging

• Compatible with AMR/OHT systems

• > 300 FOSBs/FOUPs per day

Step 1: Identification & Slot Verification

Every container correctly identified and assigned

FOSBs and FOUPs are clearly identified by RFID. Thanks to integrated cross-slot checks, the system automatically detects incorrect assignments or slot overlaps. This helps you to avoid misallocations and protect your process stability.

Functions:

• RFID-based identification

• Cross-slot verification for secure slot assignment

• Data synchronization with host systems

Step 2: Leak test and inspection

100% tested – for maximum product safety

Each packaging unit is tested for leaks before the next step. Leaks are detected and sorted out – automatically and documented. This ensures particle protection and meets the requirements for controlled environments.

Functions:

• Automated leak testing

• Testing against product-specific limit values

• Digital test protocols for each handling

Step 3: Labeling & traceability

Serial number, status, batch information – automatically labeled

All packaging units receive a tamper-proof label with a serial number, timestamp and inspection result. The information is stored digitally and is available for MES, ERP or auditing.

Functions:

• Automatic labeling with serial and batch number

• Tracking of container movements via SECS/GEM

• Compliant with cleanroom requirements

Step 4: Packaging & delivery

Standardized, hygienic, automated

After passing the test, the unit is double-packed. It is transferred to downstream processes - whether manually, via AMR or fully integrated into an existing line. Everything is documented without interruption. All required information can be passed on to downstream systems (handshake principle).

Functions:

• Cleanroom-compatible protective packaging

• Compatible with AMR/OHT systems

• > 300 FOSBs/FOUPs per day

Step 1: Identification & Slot Verification

Every container correctly identified and assigned

FOSBs and FOUPs are clearly identified by RFID. Thanks to integrated cross-slot checks, the system automatically detects incorrect assignments or slot overlaps. This helps you to avoid misallocations and protect your process stability.

Functions:

• RFID-based identification

• Cross-slot verification for secure slot assignment

• Data synchronization with host systems

Integration & system transparency

From stand-alone solution to integrated production cell

In many production environments, packaging and testing are still run in isolation – often manually and without a direct connection to traceability systems.

The ABT system closes this gap: it communicates directly with your host system via SECS/GEM and automatically transmits all test results, labeling data and container IDs. This creates an integrated, documented packaging cell – without any additional work for your team.

Optimized for your requirements

Adaptation to production-specific requirements

SECS/GEM-Ready

ABT can be immediately synchronized with existing host systems

Focus on added value

Relief for operators through remote image and video surveillance

100% traceability

100% traceable batches for each FOSB including data recording

Optimized for your requirements

Adaptation to production-specific requirements

SECS/GEM-Ready

ABT can be immediately synchronized with existing host systems

Integration & system transparency

From stand-alone solution to integrated production cell

In many production environments, packaging and testing are still run in isolation – often manually and without a direct connection to traceability systems.

The ABT system closes this gap: it communicates directly with your host system via SECS/GEM and automatically transmits all test results, labeling data and container IDs. This creates an integrated, documented packaging cell – without any additional work for your team.

Optimized for your requirements

Adaptation to production-specific requirements

SECS/GEM-Ready

ABT can be immediately synchronized with existing host systems

Focus on added value

Relief for operators through remote image and video surveillance

100% traceability

100% traceable batches for each FOSB including data recording

Optimized for your requirements

Adaptation to production-specific requirements

SECS/GEM-Ready

ABT can be immediately synchronized with existing host systems

This is how we set new standards in FOSB & FOUP packing.

While many competitors still rely on semi-automated systems in which critical inspection and packaging steps have to be supported manually, the ABT system offers an end-to-end, digitally integrated process.

From slot verification and leak testing to documented labeling, ABT works fully automatically - and thus avoids precisely those sources of error that cause rework, rejects or production downtime in other lines on a daily basis.

The result: a reliable, validated packaging process that protects your cleanroom standards and relieves your line - around the clock.

This is how we set new standards in FOSB & FOUP packing.

While many competitors still rely on semi-automated systems in which critical inspection and packaging steps have to be supported manually, the ABT system offers an end-to-end, digitally integrated process.

From slot verification and leak testing to documented labeling, ABT works fully automatically - and thus avoids precisely those sources of error that cause rework, rejects or production downtime in other lines on a daily basis.

The result: a reliable, validated packaging process that protects your cleanroom standards and relieves your line - around the clock.

This is how we set new standards in FOSB & FOUP packing.

While many competitors still rely on semi-automated systems in which critical inspection and packaging steps have to be supported manually, the ABT system offers an end-to-end, digitally integrated process.

From slot verification and leak testing to documented labeling, ABT works fully automatically - and thus avoids precisely those sources of error that cause rework, rejects or production downtime in other lines on a daily basis.

The result: a reliable, validated packaging process that protects your cleanroom standards and relieves your line - around the clock.