Safety concepts, SIL & GxP compliance for stable processes

In safety-critical industries such as chemical, pharmaceutical, and food production, process safety is the top priority.

Under Process Integrity, we ensure maximum safety, compliance, and process stability through tailored safety concepts, precise analytical technology, and traceable calibrations for your systems.

From certified SIL concepts to the selection of optimal analytical technology and GxP qualification, our solutions enable efficient workflows, minimized risks, and full compliance with industry standards.

Safety concepts, SIL & GxP compliance for stable processes

In safety-critical industries such as chemical, pharmaceutical, and food production, process safety is the top priority.

Under Process Integrity, we ensure maximum safety, compliance, and process stability through tailored safety concepts, precise analytical technology, and traceable calibrations for your systems.

From certified SIL concepts to the selection of optimal analytical technology and GxP qualification, our solutions enable efficient workflows, minimized risks, and full compliance with industry standards.

Safety concepts, SIL & GxP compliance for stable processes

In safety-critical industries such as chemical, pharmaceutical, and food production, process safety is the top priority.

Under Process Integrity, we ensure maximum safety, compliance, and process stability through tailored safety concepts, precise analytical technology, and traceable calibrations for your systems.

From certified SIL concepts to the selection of optimal analytical technology and GxP qualification, our solutions enable efficient workflows, minimized risks, and full compliance with industry standards.

Identify risks early

Structured safety and risk assessments prevent unexpected failures

Meet safety standards

Our SIL concepts and documentation comply with international regulations, ensuring legal security

Ensure compliance & audit readiness

GxP-compliant qualifications and risk analyses provide full traceability for audits and inspections

Identify risks early

Structured safety and risk assessments prevent unexpected failures

Meet safety standards

Our SIL concepts and documentation comply with international regulations, ensuring legal security

Ensure compliance & audit readiness

GxP-compliant qualifications and risk analyses provide full traceability for audits and inspections

Identify risks early

Structured safety and risk assessments prevent unexpected failures

Meet safety standards

Our SIL concepts and documentation comply with international regulations, ensuring legal security

Ensure compliance & audit readiness

GxP-compliant qualifications and risk analyses provide full traceability for audits and inspections

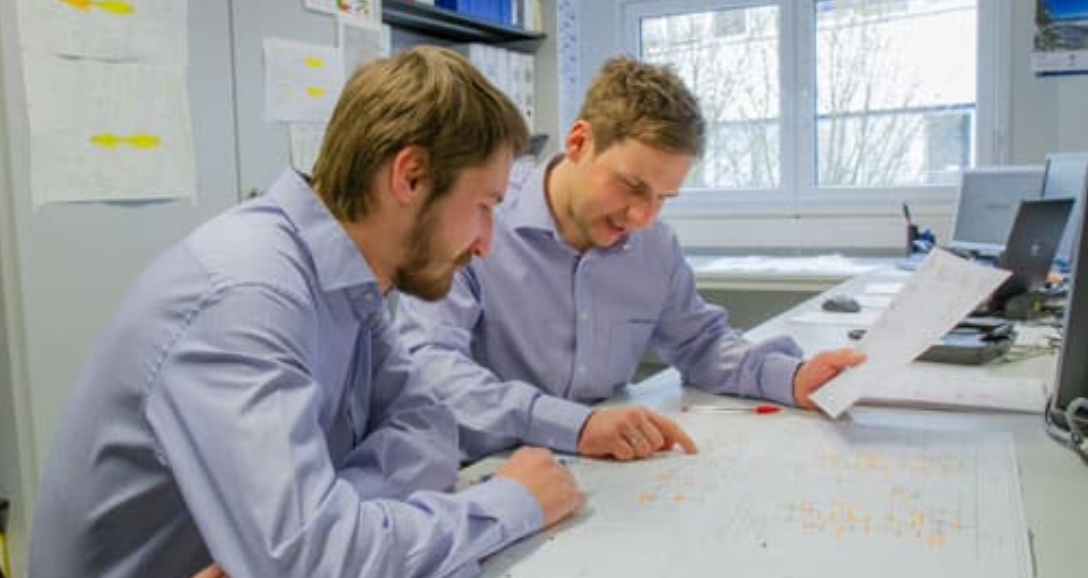

Planning, documenting and functionally testing safety functions in accordance with standards

SIL concepts & functional safety in accordance with EN 61508 and ISO 13849

Safety circuits are the backbone of any industrial plant, ensuring the protection of people, machines, and processes. A single malfunction can have serious consequences—from production downtime to safety risks for employees and the environment.

We develop SIL (Safety Integrity Level) concepts for hardware and software in compliance with EN 61508/11 and ISO 13849.

Our approach is systematic: Through precise analyses, we validate safety requirements, create clear testing protocols, and finalize on-site inspections with our in-house Functional Safety Management (FSM).

This ensures that your safety processes meet the highest standards, operate reliably, and are fully auditable.

Planning, documenting and functionally testing safety functions in accordance with standards

SIL concepts & functional safety in accordance with EN 61508 and ISO 13849

Safety circuits are the backbone of any industrial plant, ensuring the protection of people, machines, and processes. A single malfunction can have serious consequences—from production downtime to safety risks for employees and the environment.

We develop SIL (Safety Integrity Level) concepts for hardware and software in compliance with EN 61508/11 and ISO 13849.

Our approach is systematic: Through precise analyses, we validate safety requirements, create clear testing protocols, and finalize on-site inspections with our in-house Functional Safety Management (FSM).

This ensures that your safety processes meet the highest standards, operate reliably, and are fully auditable.

Certified security concepts

Early detection and prevention of safety gaps ensure reliable plant operations

On-site inspection

Structured testing and on-site verification guarantee full documentation and compliance

Conformity to standards

Our concepts fully comply with EN 61508/11 and ISO 13849 requirements

Planning, documenting and functionally testing safety functions in accordance with standards

SIL concepts & functional safety in accordance with EN 61508 and ISO 13849

Safety circuits are the backbone of any industrial plant, ensuring the protection of people, machines, and processes. A single malfunction can have serious consequences—from production downtime to safety risks for employees and the environment.

We develop SIL (Safety Integrity Level) concepts for hardware and software in compliance with EN 61508/11 and ISO 13849.

Our approach is systematic: Through precise analyses, we validate safety requirements, create clear testing protocols, and finalize on-site inspections with our in-house Functional Safety Management (FSM).

This ensures that your safety processes meet the highest standards, operate reliably, and are fully auditable.

Certified security concepts

Early detection and prevention of safety gaps ensure reliable plant operations

On-site inspection

Structured testing and on-site verification guarantee full documentation and compliance

Conformity to standards

Our concepts fully comply with EN 61508/11 and ISO 13849 requirements

Reliable analysis solutions - from device specification to maintenance

Process analytics & measurement technology for real-time monitoring of critical parameters

With the right analytical technology, we ensure that all critical process parameters are reliably monitored at all times.

We provide comprehensive support—from selecting the right analytical instruments such as gas chromatography for impurity detection or FTIR spectroscopy for real-time chemical process monitoring to installation, configuration, and regular maintenance.

This guarantees precise measurement results you can trust, giving you full control over your processes at all times.

Precise measurement results

Accurate data ensures safe processes and consistently high product quality

Holistic support

From initial consultation to maintenance, we ensure your analysis systems operate reliably

Process reliability

Early detection of deviations prevents production failures and process errors

Certified calibrations for precise, documented and auditable measured values

Traceable calibration for industrial process measurement technology

Our traceable calibrations ensure that your measurement systems for pressure, temperature, conductivity, and other critical process variables operate with absolute precision and reliability. Using state-of-the-art technology, standardized procedures, and adherence to international calibration standards, we guarantee that your measurements are accurate, documented, and always audit-ready.

This minimizes deviations, optimizes your processes, and ensures long-term process stability for your facilities.

Precise measurement results

Reliable calibrations guarantee precise monitoring of process variables

Compliance with standards

Traceable standards ensure compliance with international quality and regulatory requirements

Stable processes

Accurate measurements enable early detection of deviations and process optimization

Risk-based qualification according to GxP and GMP - traceable, safe, auditable

GxP risk analysis & GMP qualification for regulated production processes

With comprehensive GxP risk analyses (e.g., FMEA) and systematic qualification of equipment and systems according to GMP standards, we ensure that your processes run safely, stably, and in full regulatory compliance. Our approach covers the entire spectrum—from risk assessments and identification of critical weaknesses to validated implementation.

This enables you to detect risks early, implement targeted mitigation strategies, and ensure long-term compliance.

Risk assessment according to GxP

Structured risk analyses uncover vulnerabilities and enable targeted countermeasures

GMP-compliant qualification

Validated processes and systems ensure safe operations in regulated environments

Traceable processes

Documented qualifications provide transparency and full audit traceability

Reliable analysis solutions - from device specification to maintenance

Process analytics & measurement technology for real-time monitoring of critical parameters

Inaccurate measurements not only jeopardize process stability but can also lead to quality losses and increased costs.

With the right analytical technology, we ensure that all critical process parameters are reliably monitored at all times.

We provide comprehensive support—from selecting the right analytical instruments such as gas chromatography for impurity detection or FTIR spectroscopy for real-time chemical process monitoring to installation, configuration, and regular maintenance.

This guarantees precise measurement results you can trust, giving you full control over your processes at all times.

Precise measurement results

Accurate data ensures safe processes and consistently high product quality

Holistic support

From initial consultation to maintenance, we ensure your analysis systems operate reliably

Process reliability

Early detection of deviations prevents production failures and process errors

Certified calibrations for precise, documented and auditable measured values

Traceable calibration for industrial process measurement technology

Accurate measurements are the foundation of stable and efficient production processes. Even small deviations can result in quality defects, inefficient resource utilization, and costly errors.

Our traceable calibrations ensure that your measurement systems for pressure, temperature, conductivity, and other critical process variables operate with absolute precision and reliability. Using state-of-the-art technology, standardized procedures, and adherence to international calibration standards, we guarantee that your measurements are accurate, documented, and always audit-ready.

This minimizes deviations, optimizes your processes, and ensures long-term process stability for your facilities.

Precise measurement results

Reliable calibrations guarantee precise monitoring of process variables

Compliance with standards

Traceable standards ensure compliance with international quality and regulatory requirements

Stable processes

Accurate measurements enable early detection of deviations and process optimization

Risk-based qualification according to GxP and GMP - traceable, safe, auditable

GxP risk analysis & GMP qualification for regulated production processes

In highly regulated industries such as pharmaceuticals, chemicals, and food production, compliance with standards is essential for operational success and audit readiness.

With comprehensive GxP risk analyses (e.g., FMEA) and systematic qualification of equipment and systems according to GMP standards, we ensure that your processes run safely, stably, and in full regulatory compliance. Our approach covers the entire spectrum—from risk assessments and identification of critical weaknesses to validated implementation.

This enables you to detect risks early, implement targeted mitigation strategies, and ensure long-term compliance.

Risk assessment according to GxP

Structured risk analyses uncover vulnerabilities and enable targeted countermeasures

GMP-compliant qualification

Validated processes and systems ensure safe operations in regulated environments

Traceable processes

Documented qualifications provide transparency and full audit traceability

Early detection and prevention of safety gaps ensure reliable plant operations

Structured testing and on-site verification guarantee full documentation and compliance

Our concepts fully comply with EN 61508/11 and ISO 13849 requirements

Reliable analysis solutions - from device specification to maintenance

Process analytics & measurement technology for real-time monitoring of critical parameters

Inaccurate measurements not only jeopardize process stability but can also lead to quality losses and increased costs.

With the right analytical technology, we ensure that all critical process parameters are reliably monitored at all times.

We provide comprehensive support—from selecting the right analytical instruments such as gas chromatography for impurity detection or FTIR spectroscopy for real-time chemical process monitoring to installation, configuration, and regular maintenance.

This guarantees precise measurement results you can trust, giving you full control over your processes at all times.

Accurate data ensures safe processes and consistently high product quality

From initial consultation to maintenance, we ensure your analysis systems operate reliably

Early detection of deviations prevents production failures and process errors

Certified calibrations for precise, documented and auditable measured values

Traceable calibration for industrial process measurement technology

Accurate measurements are the foundation of stable and efficient production processes. Even small deviations can result in quality defects, inefficient resource utilization, and costly errors.

Our traceable calibrations ensure that your measurement systems for pressure, temperature, conductivity, and other critical process variables operate with absolute precision and reliability. Using state-of-the-art technology, standardized procedures, and adherence to international calibration standards, we guarantee that your measurements are accurate, documented, and always audit-ready.

This minimizes deviations, optimizes your processes, and ensures long-term process stability for your facilities.

Reliable calibrations guarantee precise monitoring of process variables

Traceable standards ensure compliance with international quality and regulatory requirements

Accurate measurements enable early detection of deviations and process optimization

Risk-based qualification according to GxP and GMP - traceable, safe, auditable

GxP risk analysis & GMP qualification for regulated production processes

In highly regulated industries such as pharmaceuticals, chemicals, and food production, compliance with standards is essential for operational success and audit readiness.

With comprehensive GxP risk analyses (e.g., FMEA) and systematic qualification of equipment and systems according to GMP standards, we ensure that your processes run safely, stably, and in full regulatory compliance. Our approach covers the entire spectrum—from risk assessments and identification of critical weaknesses to validated implementation.

This enables you to detect risks early, implement targeted mitigation strategies, and ensure long-term compliance.

Structured risk analyses uncover vulnerabilities and enable targeted countermeasures

Validated processes and systems ensure safe operations in regulated environments

Documented qualifications provide transparency and full audit traceability

Focus on Smart Processes

Discover how we ensure the safe and efficient operation of process engineering plants – from planning and installation to maintenance. Using cutting-edge technologies and the highest safety standards, we optimize complex processes in the chemical, pharmaceutical, and food industries.

Focus on Smart Processes

Discover how we ensure the safe and efficient operation of process engineering plants – from planning and installation to maintenance. Using cutting-edge technologies and the highest safety standards, we optimize complex processes in the chemical, pharmaceutical, and food industries.