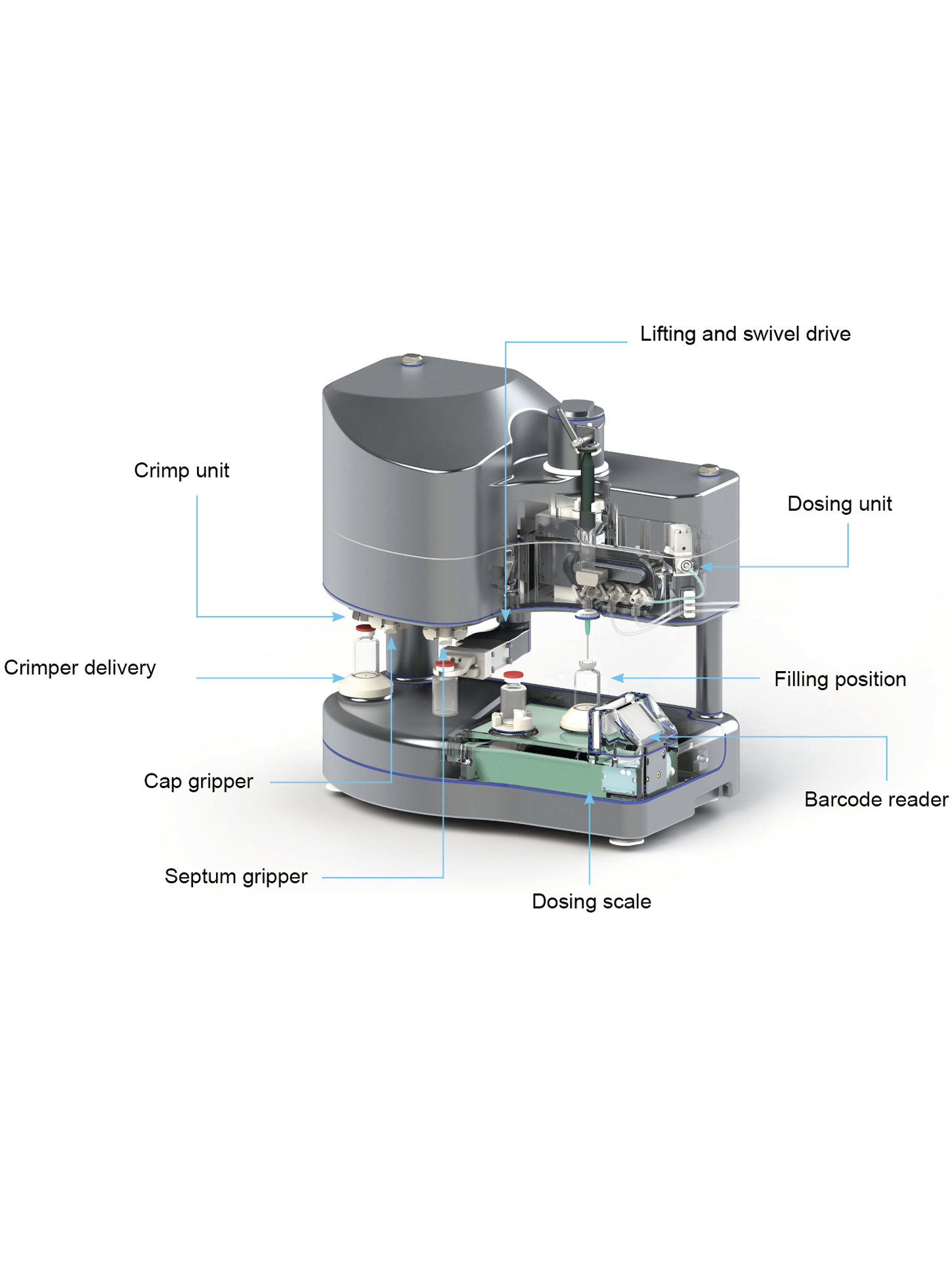

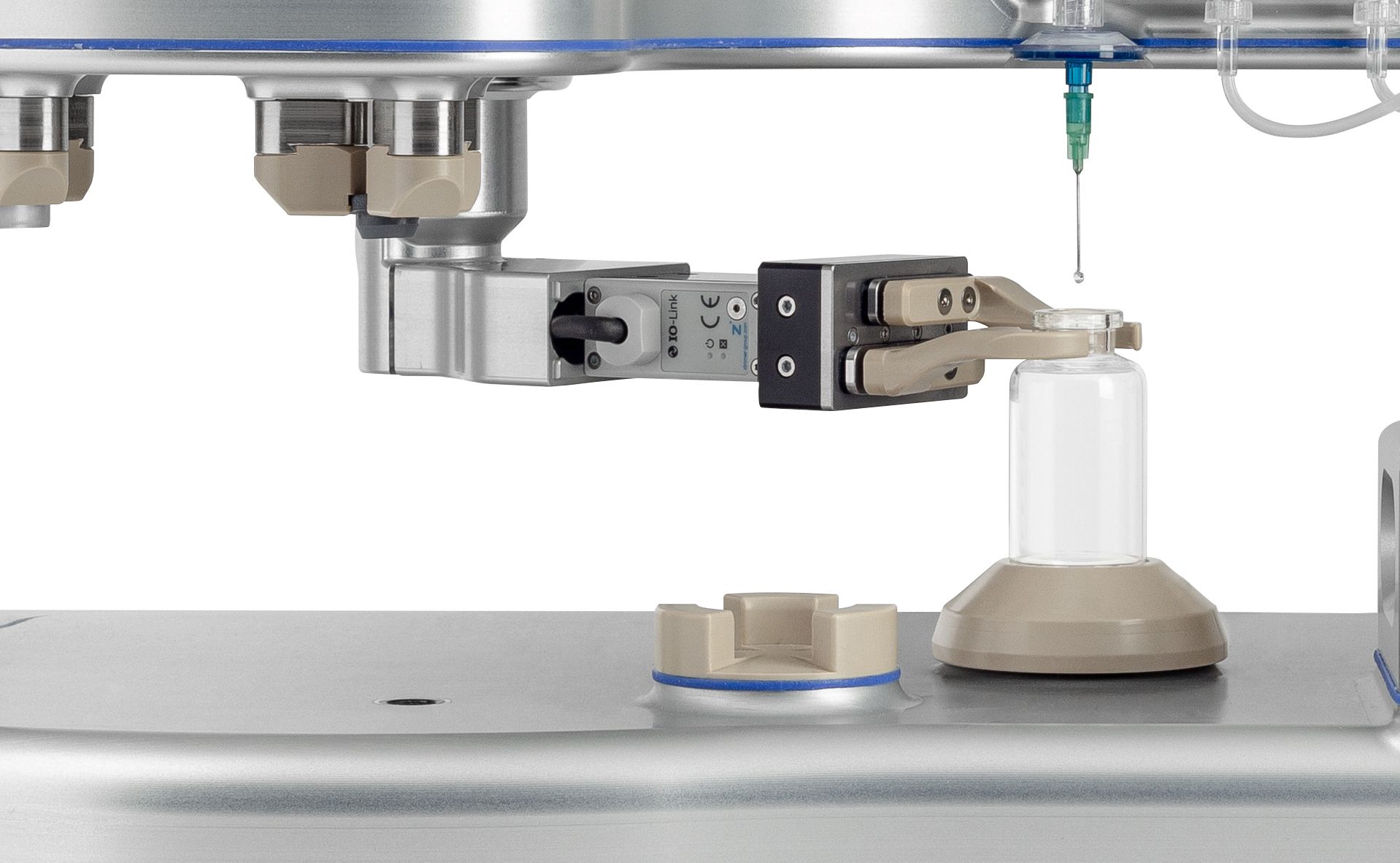

OVD: Open, precise and safe filling of radiopharmaceuticals

The precise filling of radiopharmaceuticals places the highest demands on dosing accuracy, safety and process validation. With the OVD system from the cts group, this critical production step is fully automated – for maximum patient safety, regulatory compliance and reproducible quality.

The system is specially designed for processing open vials in class A isolators and combines a space-saving design with the latest technology for validated, highly accurate dosing.

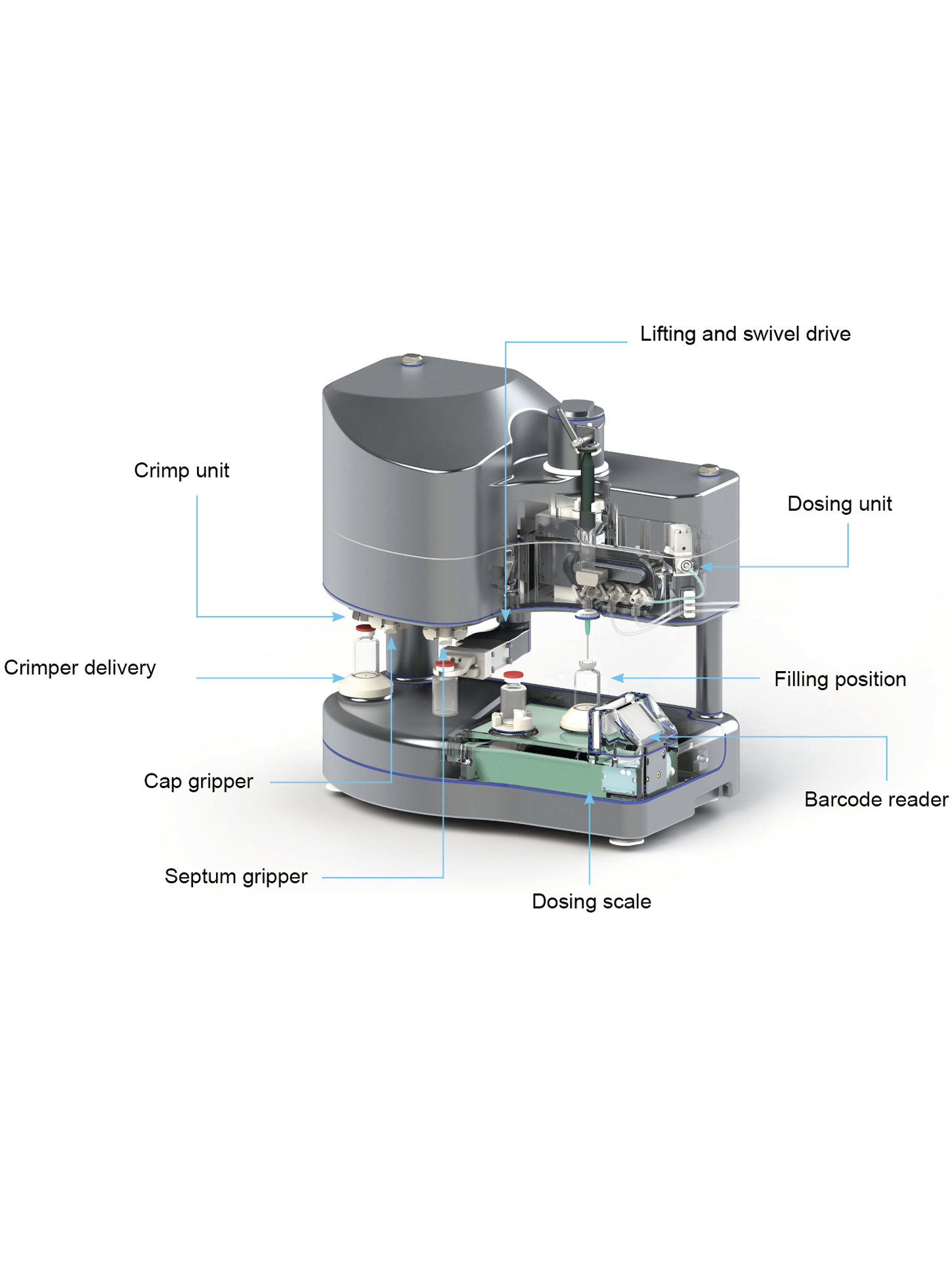

OVD: Open, precise and safe filling of radiopharmaceuticals

The precise filling of radiopharmaceuticals places the highest demands on dosing accuracy, safety and process validation. With the OVD system from the cts group, this critical production step is fully automated – for maximum patient safety, regulatory compliance and reproducible quality.

The system is specially designed for processing open vials in class A isolators and combines a space-saving design with the latest technology for validated, highly accurate dosing.

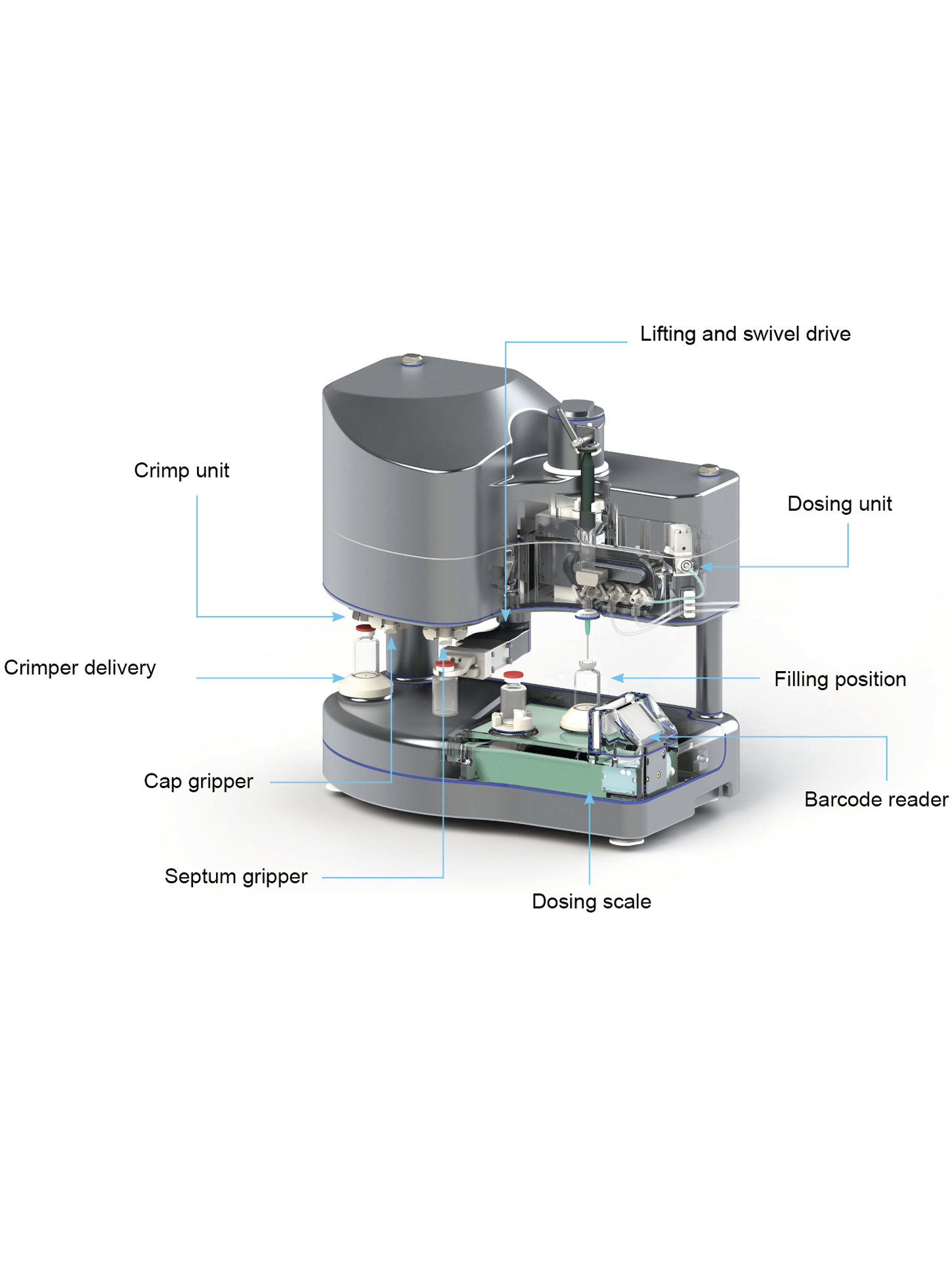

OVD: Open, precise and safe filling of radiopharmaceuticals

The precise filling of radiopharmaceuticals places the highest demands on dosing accuracy, safety and process validation. With the OVD system from the cts group, this critical production step is fully automated – for maximum patient safety, regulatory compliance and reproducible quality.

The system is specially designed for processing open vials in class A isolators and combines a space-saving design with the latest technology for validated, highly accurate dosing.

±1 µl dispensing accuracy

Self-calibrating scale with automatic adjustment

Seamless Integration

Suitable for shielded cells and class A isolators

Security and documentation

Process history to support audits and inspections

±1 µl dispensing accuracy

Self-calibrating scale with automatic adjustment

Seamless Integration

Suitable for shielded cells and class A isolators

Security and documentation

Process history to support audits and inspections

±1 µl dispensing accuracy

Self-calibrating scale with automatic adjustment

Seamless Integration

Suitable for shielded cells and class A isolators

Security and documentation

Process history to support audits and inspections

More safety, more control, more reliability.

With our OVD system, you can reduce maintenance and minimize errors – for greater efficiency and maximum safety. You retain full control over every step of the process, while your employees remain protected thanks to minimized radiation exposure. Use a solution that automates the entire process from sample collection to filling and sealing the vials.

Our OVD system optimizes your processes and gives you the assurance of working accurately and reliably at all times.

More safety, more control, more reliability.

With our OVD system, you can reduce maintenance and minimize errors – for greater efficiency and maximum safety. You retain full control over every step of the process, while your employees remain protected thanks to minimized radiation exposure. Use a solution that automates the entire process from sample collection to filling and sealing the vials.

Our OVD system optimizes your processes and gives you the assurance of working accurately and reliably at all times.

More safety, more control, more reliability.

With our OVD system, you can reduce maintenance and minimize errors – for greater efficiency and maximum safety. You retain full control over every step of the process, while your employees remain protected thanks to minimized radiation exposure. Use a solution that automates the entire process from sample collection to filling and sealing the vials.

Our OVD system optimizes your processes and gives you the assurance of working accurately and reliably at all times.

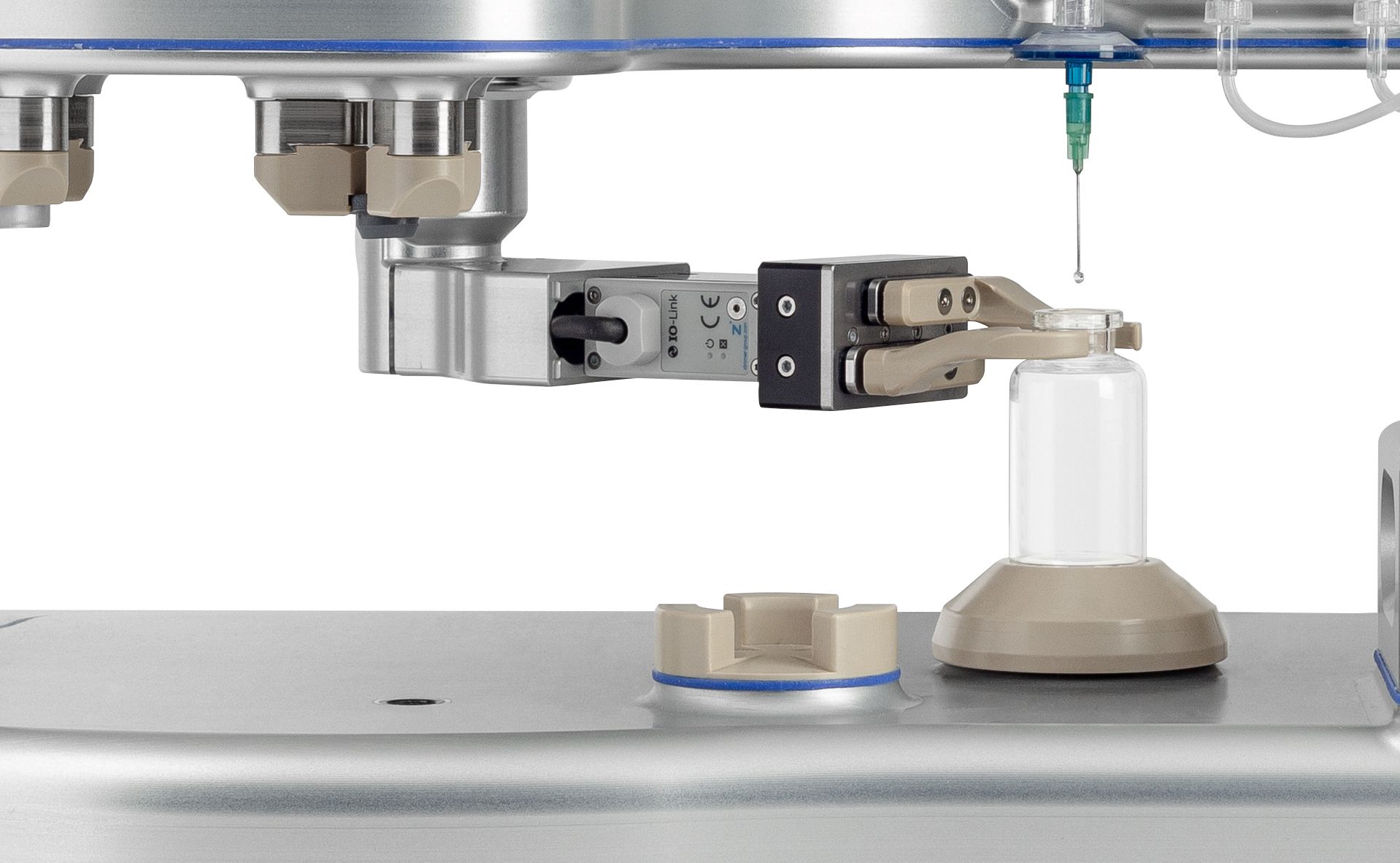

The dosing process

Automation that sets new standards

Fluctuations in measurement accuracy can not only affect the effectiveness of the medication, but also cost time and lead to increased material consumption.

Gravimetric measurement enables precise determination of the filled volume by continuously monitoring and calibrating the weight. This ensures that each filling is exactly as specified.

Fast and precise

Dispensing up to 100 vials per hour with a final accuracy of ±1 µl

Detailed from A to Z

Combines weight control with dosing accuracy

Security & Compliance

Monitors and controls the filled volume in the process

Self-calibrating scale

Exact, patient-specific dosage

Manual or non-automated scales are subject to measurement deviations. These inaccuracies affect drug efficacy and increase batch losses.

The OVD system's self-calibrating scale eliminates measurement deviations by making automatic adjustments during operation. This technology ensures consistent dosing accuracy.

Consistency

Self-calibration ensures consistent accuracy of ±1 µl

No deviations

Prevents over- and underdosing

Error minimization

Stable workflow and error-free batches

Barcode reader

Security without compromise

In existing systems, barcode scanners or readers are often exposed to direct radiation, which shortens their lifespan and can affect the reliability of data collection.

The barcode reader of the OVD system is installed in such a way that it is protected from direct radiation. This extends its lifespan and ensures error-free identification of the vials, as well as seamless traceability.

Transparency

Guaranteed seamless assignment and traceability

Longevity

Reduces maintenance costs and system failures

Security & Compliance

Optimizes quality assurance and regulatory compliance

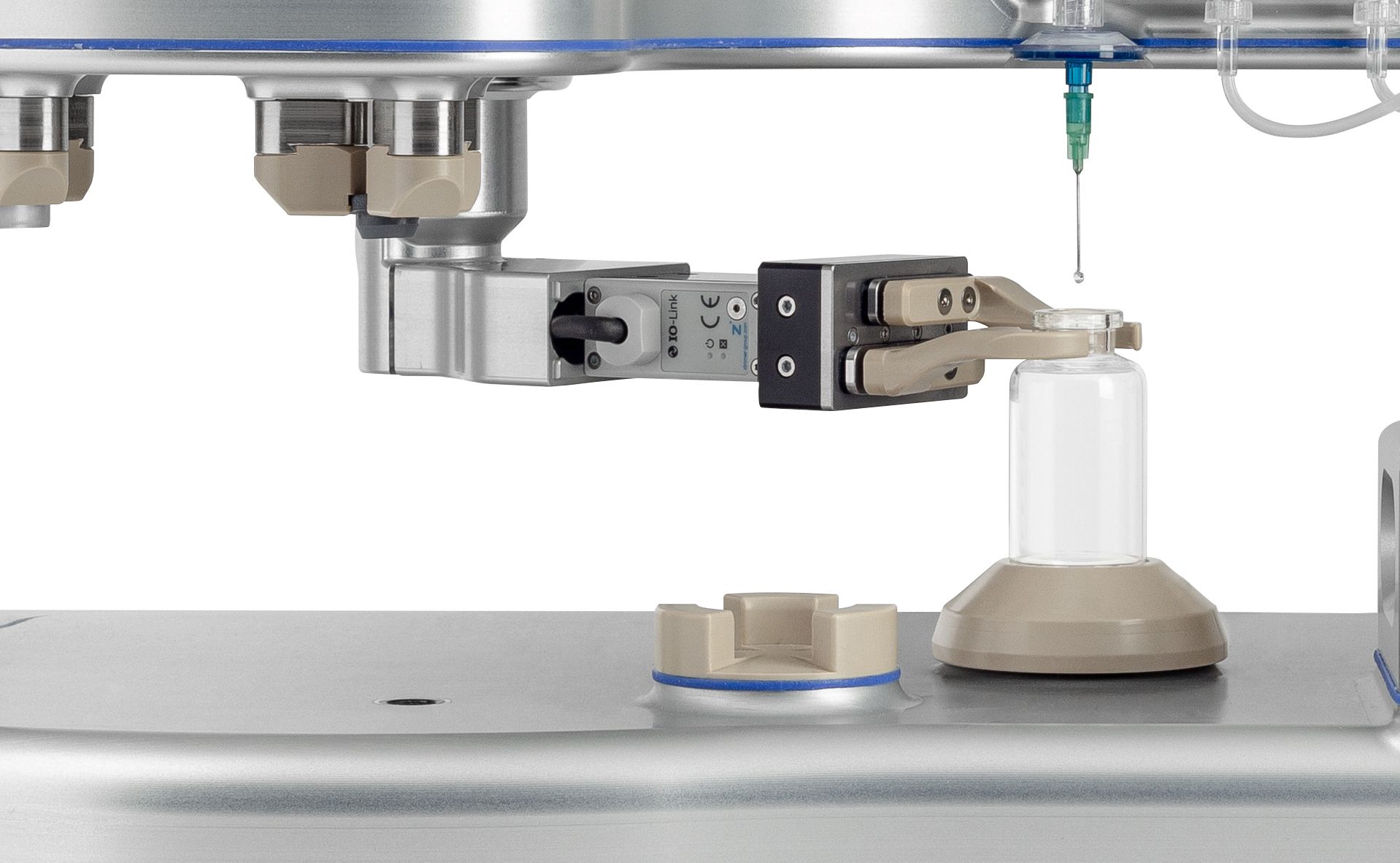

Automated movement

The linear-rotary actuator replaces Teleplier

Manual telepliers are often inaccurate, slow and prone to error. Mechanical restrictions lead to material loss, longer process times and increased radiation exposure.

The automatic linear-rotary actuator optimizes the vial movement process by providing repeatable, fluid motion that minimizes material loss and increases the efficiency of the entire process.

Error minimization

Reduces errors and expensive material losses

Enhanced security

Increases safety and reduces the burden on the team

Improved processes

Accelerates vial handling and improves processes

This is how we stand out from the competition.

While competitors often rely on semi-automatic or less precise systems, the CTs Group offers fully automated solutions. The result: more precise dosing, more reliable processes and less downtime – a clear advantage for your production.

The dosing process

Automation that sets new standards

Fluctuations in measurement accuracy can not only affect the effectiveness of the medication, but also cost time and lead to increased material consumption.

Gravimetric measurement enables precise determination of the filled volume by continuously monitoring and calibrating the weight. This ensures that each filling is exactly as specified.

Fast and precise

Dispensing up to 100 vials per hour with a final accuracy of ±1 µl

Detailed from A to Z

Combines weight control with dosing accuracy

Security & Compliance

Monitors and controls the filled volume in the process

Self-calibrating scale

Exact, patient-specific dosage

Manual or non-automated scales are subject to measurement deviations. These inaccuracies affect drug efficacy and increase batch losses.

The OVD system's self-calibrating scale eliminates measurement deviations by making automatic adjustments during operation. This technology ensures consistent dosing accuracy.

Consistency

Self-calibration ensures consistent accuracy of ±1 µl

No deviations

Prevents over- and underdosing

Error minimization

Stable workflow and error-free batches

Barcode reader

Security without compromise

In existing systems, barcode scanners or readers are often exposed to direct radiation, which shortens their lifespan and can affect the reliability of data collection.

The barcode reader of the OVD system is installed in such a way that it is protected from direct radiation. This extends its lifespan and ensures error-free identification of the vials, as well as seamless traceability.

Transparency

Guaranteed seamless assignment and traceability

Longevity

Reduces maintenance costs and system failures

Security & Compliance

Optimizes quality assurance and regulatory compliance

Automated movement

The linear-rotary actuator replaces Teleplier

Manual telepliers are often inaccurate, slow and prone to error. Mechanical restrictions lead to material loss, longer process times and increased radiation exposure.

The automatic linear-rotary actuator optimizes the vial movement process by providing repeatable, fluid motion that minimizes material loss and increases the efficiency of the entire process.

Error minimization

Reduces errors and expensive material losses

Enhanced security

Increases safety and reduces the burden on the team

Improved processes

Accelerates vial handling and improves processes

This is how we stand out from the competition.

While competitors often rely on semi-automatic or less precise systems, the CTs Group offers fully automated solutions. The result: more precise dosing, more reliable processes and less downtime – a clear advantage for your production.

The dosing process

Automation that sets new standards

Fluctuations in measurement accuracy can not only affect the effectiveness of the medication, but also cost time and lead to increased material consumption.

Gravimetric measurement enables precise determination of the filled volume by continuously monitoring and calibrating the weight. This ensures that each filling is exactly as specified.

Doses up to 100 vials per hour with a final accuracy of ±1 µl

Combines weight control with dosing accuracy

Monitors and controls the filled volume in the process

Self-calibrating scale

Exact, patient-specific dosage

Manual or non-automated scales are subject to measurement deviations. These inaccuracies affect drug efficacy and increase batch losses.

The OVD system's self-calibrating scale eliminates measurement deviations by making automatic adjustments during operation. This technology ensures consistent dosing accuracy.

Self-calibration ensures consistent accuracy of ±1 µl

Prevents over- and underdosing

Stable workflow and error-free batches

Barcode reader

Security without compromise

In existing systems, barcode scanners or readers are often exposed to direct radiation, which shortens their lifespan and can affect the reliability of data collection.

The barcode reader of the OVD system is installed in such a way that it is protected from direct radiation. This extends its lifespan and ensures error-free identification of the vials, as well as seamless traceability.

Guaranteed seamless assignment and traceability

Reduces maintenance costs and system failures

Optimizes quality assurance and regulatory compliance

Automated movement

The linear-rotary actuator replaces Teleplier

Manual telepliers are often inaccurate, slow and prone to error. Mechanical restrictions lead to material loss, longer process times and increased radiation exposure.

The automatic linear-rotary actuator optimizes the vial movement process by providing repeatable, fluid motion that minimizes material loss and increases the efficiency of the entire process.

Reduces errors and expensive material losses

Increases safety and reduces the burden on the team

Accelerates vial handling and improves processes

This is how we stand out from the competition.

While competitors often rely on semi-automatic or less precise systems, the CTs Group offers fully automated solutions. The result: more precise dosing, more reliable processes and less downtime – a clear advantage for your production.