Why Manual Material Handling is the Critical SMT Bottleneck in the UK Market

Electronics manufacturing in the United Kingdom, just like all over Europe, is facing a critical phase. While the speed and precision of SMT lines are continuously increasing, material flow – the logistics of components from the warehouse to the placement machine – is increasingly proving to be the decisive bottleneck. Manual processes lead to inefficiency, jeopardise compliance and limit scalability.

How can British manufacturers break this vicious circle and future-proof their production?

We talk to Terry Morgan, an expert at cts Group for the British market. Terry highlights the biggest challenges facing SMT intralogistics in the UK, presents cts Group's Smart Electronics Factory solutions based on autonomous systems and highly customisable machines, and explains how a focus on configurability makes all the difference.

A conversation that shows how manual tasks can be made efficient, safe and reproducible, why automation does not necessarily mean rationalising jobs, and why choosing a partner who not only provides technology but also tailor-made process optimisation is crucial for return on investment (ROI).

Material Flow as a Hidden Cost Factor

In the SMT environment, material flow is often underestimated as a non-productive ancillary activity. Where exactly do you see the biggest bottlenecks and efficiency losses in the traditional intralogistics of British electronics manufacturers?

Terry: In a lot of UK SMT plants, the real bottlenecks come from the everyday material handling that’s still done manually. Operators spend far too much time walking around, hunting for the right materials, or dealing with paper-based tracking, and all of that slows down changeovers and drags down line utilisation. On the back end, moving finished boards by hand often causes unpredictable flow and creates queues at inspection and test, especially when volumes ramp up or drop suddenly. These manual steps also open the door to mistakes that hit traceability and quality.

Automation changes the picture completely. By shifting to predictable, data-driven movement—using smart storage, AMRs, and

Challenges of Volatility

Material demand at SMT lines is highly volatile. What specific risks arise from manual or inefficient material supply in terms of production stops, incorrect dosing, or scrap?

Terry: When demand on the SMT line changes quickly, any manual weakness in material supply becomes a real risk. The biggest issue is simple: if a component is missing or misplaced, the line stops – and that can cost a lot in a very short time.

To avoid this, teams often pre-pick material far earlier than required, which eats up valuable space around the line. This is made worse by the build-up of open materials that have to be put away after tear-downs during changeovers. Magazines and trays end up everywhere, increasing the chance of parts being damaged or sitting out too long and exceeding their exposure limits. On top of that, manual dosing or replenishment can easily lead to errors or scrap. Automation removes these risks by delivering the right material to the right place at the right time, every time.

Traceability Requirements

With a view to compliance and quality assurance, what minimum requirements do UK SMT manufacturers place on the precision and continuous traceability of components both in the warehouse and at the line?

Terry: For UK manufacturers, precision and traceability aren’t “nice to have” – they’re the baseline for staying compliant and maintaining quality. At a minimum, they expect every component to be accurately identified, recorded, and traceable from the moment it enters the warehouse right through to the point it’s placed on the PCB and beyond. That means real-time tracking of batch data, storage conditions, exposure times, and every movement in between.

Anything manual creates gaps, and gaps create risk – whether that’s feeding the wrong reel, losing visibility during changeovers, or failing an audit. Automated systems remove that uncertainty by ensuring every component is accounted for, at every step, without relying on memory or paperwork.

Technological Responses to global challenges: The "Smart Warehouse" as a Solution

How does the cts Group address these bottlenecks with its Smart Warehouse concepts (e.g., Warehouse for SMT Reels, or the Mini/Big Smart Warehouse for PCB magazines and more) and how is the required high level of precision and efficiency guaranteed?

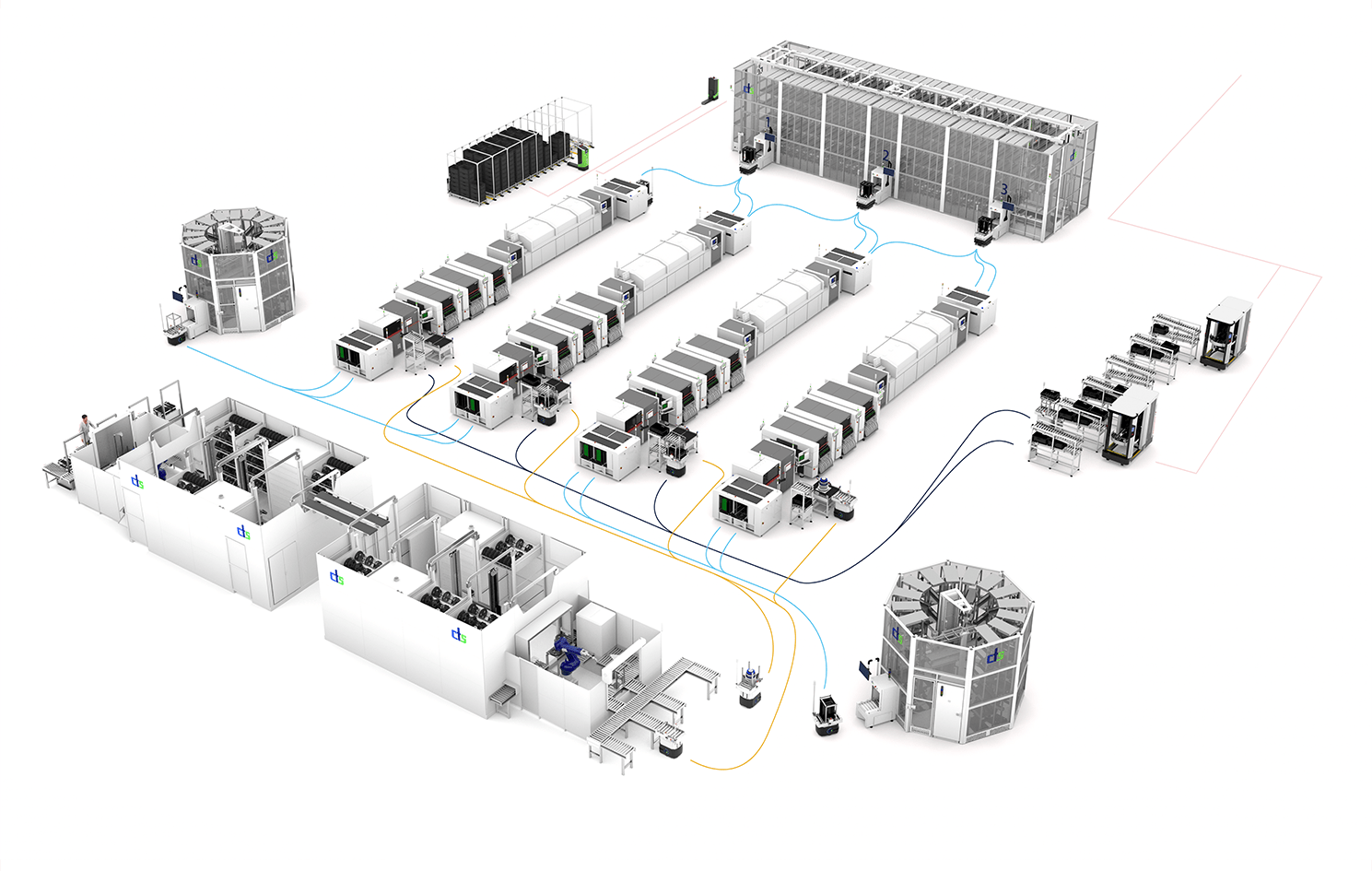

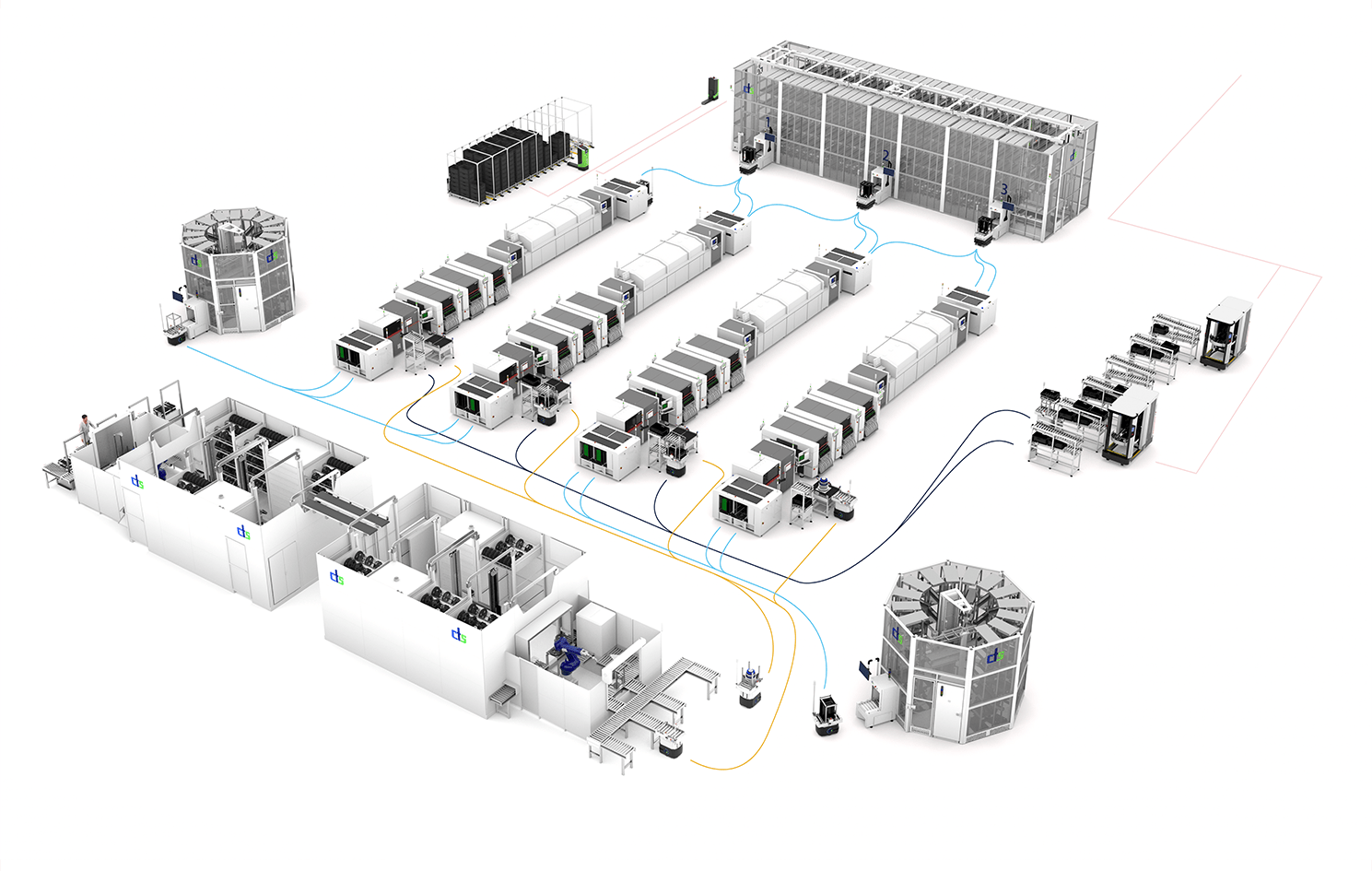

Terry: The cts Group tackles these bottlenecks by removing manual variability from the entire material flow. Our Smart Warehouse systems – whether it’s the SMT Reel Warehouse or the Mini and Big Smart Warehouse – are designed to manage all production materials: reels, PCBs, and components stored in magazines, trays, or boxes. Instead of operators searching through shelves or staging materials around the line, everything is held in a high-density, fully automated environment where each item is tracked, verified, and instantly accessible.

Precision comes from full digitalisation. Every material carrier type is scanned, logged, and stored with exact location data, exposure tracking, and full traceability. Efficiency comes from automation – intelligent software, automated picking, and AMRs that deliver materials directly to the right place without delays or mix-ups.

Another key strength is how well our technology integrates with a customer’s existing MES or MOM systems. This is where cts’s engineering expertise really shows. We don’t replace what’s already working; we connect to it. Our hardware and software exchange real-time data with the customer’s platforms, so material status, work orders, routing, and traceability all flow seamlessly across the entire production process.

In short, the Smart Warehouse guarantees speed, accuracy, and repeatability across all material categories—supported by deep integration that ensures every item is stored correctly, picked correctly, and delivered exactly where it needs to be, every time.

Autonomous Movement

Autonomous Mobile Robots (AMRs) are a central element for smooth material flow. How do AMRs, in conjunction with transfer systems, change intralogistics, and what is the concrete benefit of this system to customers not only in the UK market?

Terry: AMRs fundamentally change intralogistics by taking over all the repetitive walking, carrying, and manual transfer tasks that slow production down. When you combine AMRs with automated transfer systems – whether that’s carts, lifts, buffer stations, or line-side loading – you create a continuous, hands-off material flow from the warehouse to the line and back again. Materials move exactly when and where they’re needed, without waiting for an operator to become available.

For customers, the benefit is very clear. You get consistent, predictable delivery, which stabilises changeovers, prevents line stoppages, and removes the guesswork from replenishment. AMRs also free up operators to focus on higher-value tasks instead of spending hours walking parts around the factory. And because every movement is tracked, the whole process becomes far more transparent and traceable.

This isn’t just a UK challenge – manufacturers everywhere are under pressure to increase flexibility, reduce labour dependency, and protect uptime. AMRs deliver that by creating a scalable, modular logistics layer that grows with production demands. It’s automation that strengthens quality, efficiency, and resilience no matter where you’re operating.

Future-Proofing through Scalability

Given the rapid pace of technological change: How does the cts Group ensure that its solutions for electronics manufacturing are future-proof, scalable, and adaptable, to offer maximum flexibility even tomorrow?

Terry: The pace of change in electronics manufacturing is only getting faster, so our approach at cts is to design every solution with scalability and adaptability built in from day one. All our systems – whether it’s Smart Warehouses, AMRs, or bespoke handling equipment – use a modular architecture, meaning customers can start with what they need today and expand as their production grows or shifts. You don’t have to rip out existing infrastructure; you simply add capacity, new modules, or new functions as required.

A big part of being future-proof is openness. Our hardware and software are built to integrate with whatever MES, MOM, or ERP platform a customer already uses, and we update interfaces as those systems evolve. That way, data flows cleanly across the factory, even as digital requirements change.

We also engineer our platforms so that new product types, new packaging formats, or new line layouts can be absorbed without redesigning the whole factory. Whether volumes ramp up, product variants multiply, or new compliance rules come in, the system adapts rather than becoming a bottleneck.

In short, we ensure future-proofing by offering solutions that can grow, reconfigure, and evolve alongside the customer – keeping them competitive not just today, but in the years ahead.

Configuration over Standardisation

Many automation providers offer rigid, off-the-shelf systems. How does the cts Group's core competency in Smart Machinery Engineering and individually adaptable equipment allow UK customers to integrate solutions seamlessly without having to redesign their entire production layout?

Terry: Many automation systems on the market are rigid, which forces manufacturers to change their layout or processes just to make the technology fit. At cts, it's the opposite. Our Smart Machinery Engineering is built around adaptability, so the equipment conforms to the customer’s environment – not the other way around. We design storage, handling, and AMR solutions that fit into existing lines, work with current MES or MOM systems, and match the available floor space.

For UK manufacturers, this means they can introduce automation without costly reconfiguration or downtime. They get seamless integration, better flow, and full scalability – without having to rebuild the factory around it.

Economics and ROI for Electronic Manufacturers in the UK

How can the Return on Investment of material handling and material flow automation projects be convincingly demonstrated, and what business arguments underpin the investment in a "Smart Electronics Factory"?

Terry: The ROI for material flow automation is easy to demonstrate because the gains show up immediately in measurable KPIs. We look at reductions in line stoppages from missing materials, faster changeovers, fewer operator hours spent walking or searching, and lower scrap from feeding or exposure mistakes. Once replenishment and tracking are automated, OEE increases, which is a major driver of the business case.

There’s also the demographic challenge: it’s becoming harder to recruit and retain skilled operators for repetitive logistics tasks. Automation fills that gap, ensuring consistency while freeing people for higher-value work. Ultimately, a

Smart Electronics Factory delivers stronger quality, better planning, and a scalable foundation for future growth.

SMT manufacturing worldwide is coming under increasing pressure. In Europe, high energy costs and a shortage of skilled workers are consuming resources, while production space is scarce. In North America, unstable supply chains and high employee turnover are causing uncertainty. In Asia, on the other hand, ongoing price pressure is forcing companies to maximize efficiency.

A conversation about material flow, service, spare parts, and line availability.

Expectations at the Southern Manufacturing and Automation Show 2026

What can visitors, particularly technical decision-makers and SMT specialists, expect to see, learn, and discuss with the cts team at the Southern Electronics and Manufacturing Trade Show?

Terry: We’re really looking forward to welcoming visitors to Southern Manufacturing this year, and we’d love anyone interested in smarter intralogistics to stop by stand M130. They’ll be able to get a hands-on look at how cts brings smart storage, AMRs, and automated transfer systems together as one connected solution. Technical decision-makers can explore real use cases, see how our systems tie into existing MES and MOM platforms, and understand the impact on changeovers, OEE, and traceability.

Most importantly, it’s a friendly space to talk through their own challenges with our engineers and see how a single-source, fully configurable automation approach can fit their factory.

Ready to tackle Your SMT Handling Bottlenecks in the UK?

The shift from manual material handling to autonomous intralogistics is key to maximizing line utilization and ensuring compliance. Talk to the experts who tailor the solution to your factory.

Contact the

manufacturing automation specialists at cts Group Factory Automation today to discuss a highly configurable Smart Warehouse and AMR solution for your SMT environment.