Optimal positioning of material carriers: line, buffer, or warehouse?

In modern electronics manufacturing, the correct positioning of material carriers—trays, magazines, and boxes – is foundational to maintaining an uninterrupted supply chain, from storage right through to final assembly and finished goods.

As production mixes grow more complex and the demand for full traceability intensifies, factories face a critical decision: does a specific carrier belong on the line, in a near-line buffer, or in central storage?

To discuss the strategy behind these critical placement decisions, we sat down with Tomas Sevcik, Sales Manager for Factory Automation at cts Group.

Sevcik highlights how cts ensures every carrier type – be it an RFID-enabled smart tray, a PCB magazine, or a moisture-sensitive IC tray – is not only in the right place at the right time but is also universally compatible with their adaptive AMR top module designs. This compatibility, he explains, is key to eliminating bottlenecks and keeping intralogistics flows optimized across the entire factory.

Basic principles for placement decisions

Tomas, when it comes to positioning material carriers, what basic principles does cts use to determine whether a carrier should be placed directly on the line, in a buffer, or in central storage?

Tomas: At cts, these decisions are based on four key criteria to ensure carriers are optimally positioned according to actual production demand, not just convenience:

Frequency of Access:

- Carriers with high turnover – think of reels for SMT feeders or PCB magazines for continuous line changeovers – remain on or near the line.

- Medium-frequency carriers are staged in near-line buffers.

- Anything with low frequency is held in central storage until its actual demand approaches.

Process Timing and Sequencing:

- Carriers for the current job are positioned at the line.

- Materials for upcoming jobs are staged in buffers to guarantee quick retrieval.

- All others wait in central storage until their demand window nears.

Space Efficiency:

- Line-side space is highly constrained and is reserved strictly for carriers in active use.

- Buffers act as controlled extensions of the line. They prevent congestion while maintaining rapid access.

- Central storage ensures order, density, and long-term traceability.

Material Characteristics:

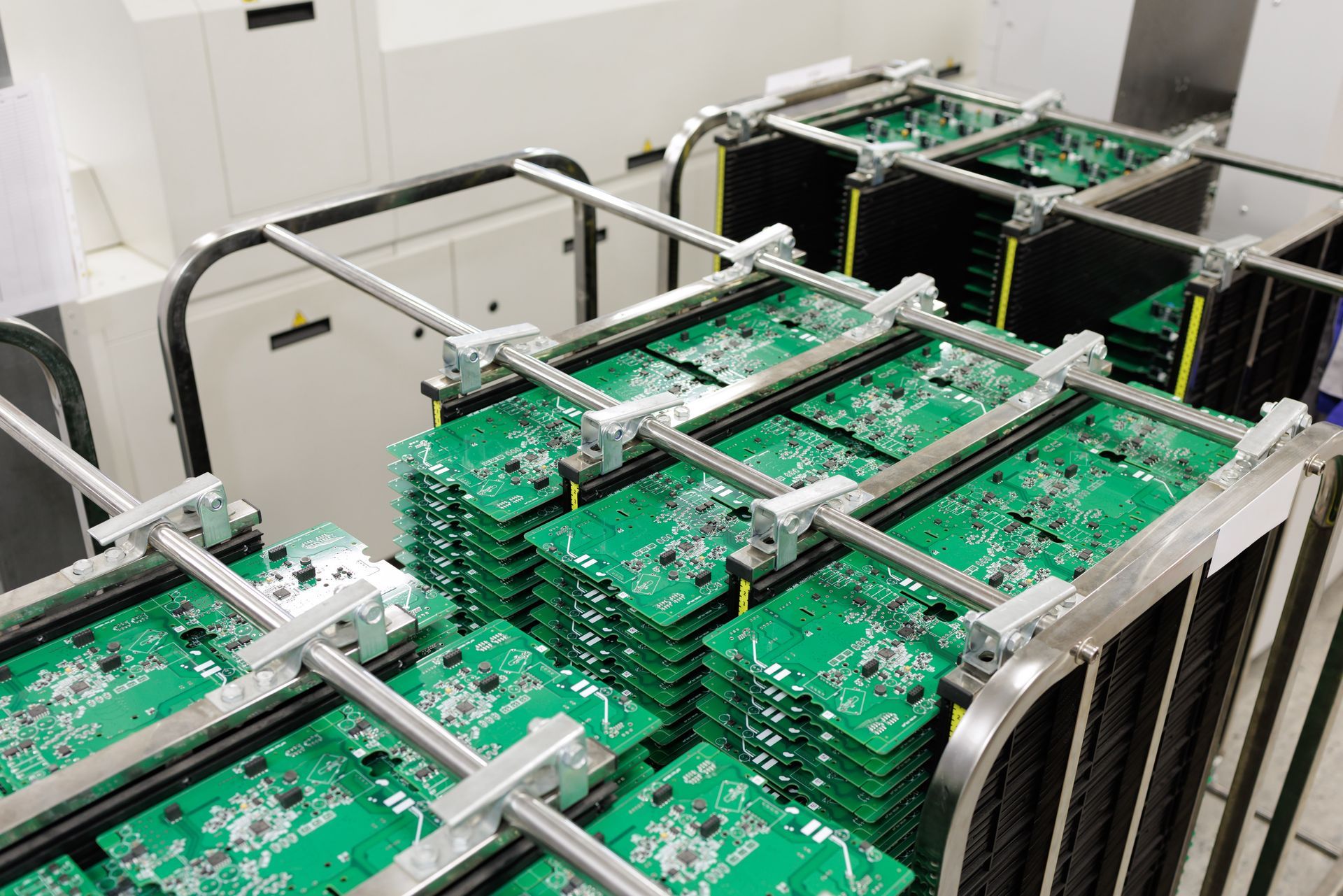

- Bulky PCB magazines require structured buffer staging to prevent them from obstructing operators.

- Other materials, such as bare PCBs, may be supplied in magazines for automated changeover or in boxes/trays for manual loading, depending on the process setup.

Crucially, by rigorously applying these four principles, we transform material positioning from a logistical afterthought into a finely-tuned component of the production process, directly supporting higher throughput and minimizing line stops.

Typical sources of error in practice

Errors in material placement seem minor, but what is the actual impact on operations? What happens if carriers are supplied too early, too late, or simply in the wrong location within the process?

Tomas: Improper placement is not a minor inconvenience; it creates significant operational risk and measurable inefficiencies across the board. We categorize the impact into three main issues:

Supplied Too Early (Excess WIP):

- This leads to excess Work in Progress (WIP) building up. The line becomes cluttered, which drastically increases the risk of human error during crucial tasks like feeder setup or PCB magazine changeovers.

Supplied Too Late (Stoppages):

- Delayed trays, reels, or PCB magazines are the most expensive mistake. They directly cause machine stoppages and necessitate disruptive, high-cost emergency transports.

Wrong Place (Non-Value-Adding Time):

- When carriers are stored incorrectly – for instance, trays left in central storage instead of being correctly staged in a buffer – it forces operators to search for materials. This adds substantial non-value-adding handling time to the process.

These placement errors fundamentally reduce line productivity. More critically, they elevate the risk of quality escapes and can lead to serious compliance issues in traceability-critical applications, which is unacceptable in today's manufacturing landscape.

Role of carrier type and frequency of use

You mentioned that material characteristics are key. How do the various carrier types – specifically reels, trays, and PCB magazines – and their respective frequency of access ultimately influence the decision about where they should be stored?

Tomas: The carrier type fundamentally dictates its storage and handling protocols. Each variant has unique requirements that influence its optimal placement:

SMT-Reels (High Frequency):

- These are the high-turnover items for SMT placement. They are best managed in automated storage solutions and must be constantly replenished near-line to guarantee the fastest possible access and zero line stops.

Trays (Lower Frequency, Precision Components):

- Trays carry sensitive components like ICs and fine-pitch devices. They are typically lower frequency, requiring placement in a buffer or controlled storage area. For MSL-sensitive components (Moisture Sensitivity Level), their trays must strictly adhere to JEDEC-compliant storage protocols.

PCB Magazines (Bulk and Critical Timing):

- Used for both bare and assembled PCBs, their bulkiness requires structured buffer staging. However, their critical role in automatic line changeovers makes their timely availability absolutely non-negotiable.

Boxes/Trays for Bare PCBs (Manual Loading):

- Fo lines involving manual loading processes, raw PCBs are supplied in protective boxes or trays. These must be strategically staged to ensure the operators can feed the line without interruption.

The common thread is intelligent tracking. When combined with smart carrier technology – like RFID, NFC tags, or even barcodes – every single carrier type gains a unique identity. This allows us to track and verify it across all stages of handling, regardless of whether it's a high-turnover reel or a low-frequency, sensitive IC tray.

Interactions with replenishment processes

The placement rules are clear, but how does the physical delivery happen? How do you effectively coordinate the storage and placement logic with the transport control – such as AMRs or route trains – to successfully avoid both material losses and delays?

Tomas: Effective replenishment is entirely dependent on seamless, integrated coordination between the placement rules and the transport systems. At cts, we achieve this predictable, just-in-time flow through five key mechanisms:

Defined Handover Points:

- We establish clear, standardized handover points between the central storage, the buffers, and the line staging areas. This removes ambiguity in the material flow.

MES/MOM-Driven Triggers:

- The material release is not manual; it is driven by MES/MOM (Manufacturing Execution System / Manufacturing Operations Management) triggers for true just-in-time material delivery.

Integrated Transport Control:

- The transport integration with AMRs, AGVs, or route trains ensures a highly predictable and reliable flow throughout the factory.

Smart Carrier Verification:

- We utilize smart carriers equipped with RFID, NFC, or barcodes for automatic identification, location tracking, and content verification at every single transfer point.

Universal AMR Compatibility:

- Crucially, our adaptive AMR top module designs universally accept all carrier types—reels, trays, boxes, and magazines – without any modification.

This high level of alignment is what prevents critical bottlenecks, minimizes manual handling effort, and guarantees a consistent, fully traceable material flow from end to end.

Recommended approach in the project

To conclude, setting up these systems must be complex. What is the recommended approach? How does cts systematically proceed to develop a suitable warehouse architecture that meets the diverse needs of different material carriers and the specific requirements of the line?

Tomas: You are right; it requires a structured approach. At cts, we follow a rigorous, six-stage project methodology to ensure robust and scalable solutions:

- Analysis: We start by thoroughly mapping the existing landscape: all carrier types, their demand patterns, and specific handling requirements, which includes bare PCBs and highly sensitive MSL materials.

- Zoning: Based on the frequency of access determined in the analysis, we precisely define and zone the line-side, buffer, and central storage areas.

- Integration: We align the MES/MOM replenishment triggers with the transport logic of our AMRs to create a single, synchronized system.

- Technology Enablement: This involves equipping carriers with RFID/NFC for full visibility and, critically, ensuring universal AMR acceptance across all carrier types.

- Validation: We don't implement without testing. We pilot and simulate flows extensively to verify the replenishment timing, check carrier compatibility, and confirm the overall intralogistics stability.

- Scaling: Once validated, we implement and scale the solution across the SMT, assembly, and finished goods logistics areas for consistent, company-wide operations.

This methodical approach guarantees that every carrier – be it a PCB magazine, an RFID-tracked tray, or a Reel carrier – is seamlessly managed, reliably transported, and delivered exactly where it needs to be, precisely when it is required.

Optimize Your Intralogistics

Are you facing challenges in implementing structured, traceable, and highly efficient material flow in your plant?

Contact the manufacturing automation experts at cts Group

Factory Automation to discuss a customized warehouse architecture and explore the automation options in your SMT manufacturing environment.