cts develops high-tech solutions and sets new standards

cts - more. than. automation. - is more than just a slogan for the machine builder and automation specialist cts!

cts - more. than. automation. - is more than just a slogan for the machine builder and automation specialist cts! The company offers the highest level of expertise in all areas of process and production automation as well as advanced solutions in industrial data processing and energy technology.

Founded in 2006, the company employs more than 350 people and has its headquarters in Burgkirchen in southern Germany. Further branches/offices in Germany are located in Abensberg, Penzberg and Leipzig. A large part of the workforce works in Austria in Vienna, Schörfling am Attersee, Lenzing, Raaba-Grambach and Linz. There are also other representative offices and partners in Europe, America and Asia. More than 1,000 satisfied customers from demanding sectors such as the pharmaceutical, electronics and semiconductor industries are impressive proof of the company's excellent reputation.

Significant increase in quality and safety during packaging

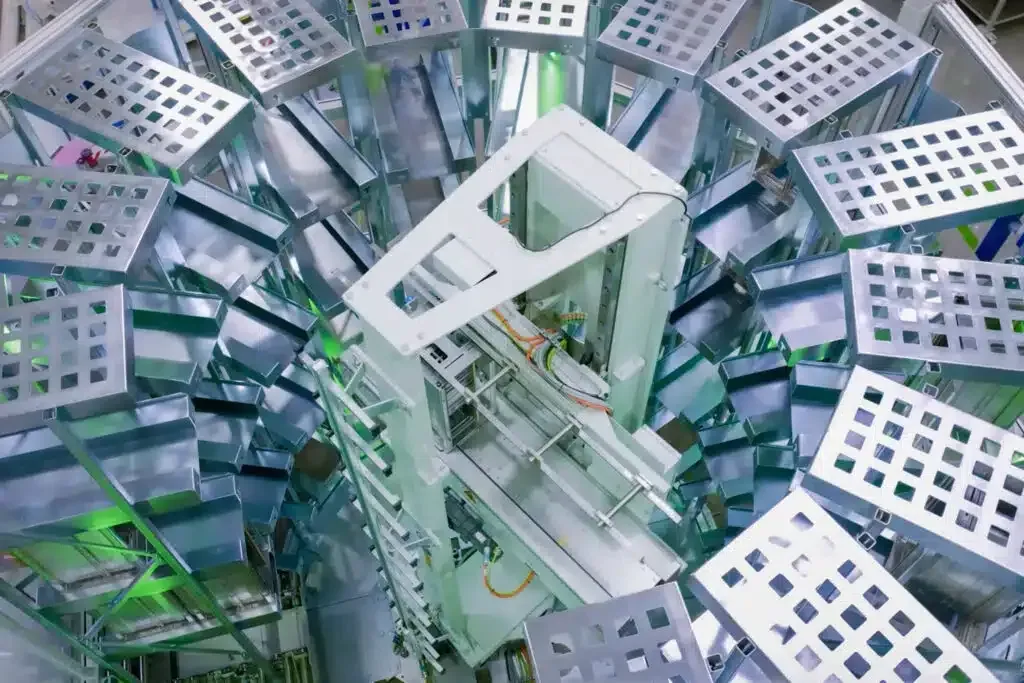

“We are very broadly positioned and are constantly expanding our range of products and services,” reports Alfred Pammer, authorized signatory of cts GmbH. ‘Our goal is to develop high-tech solutions for our customers and set new standards in the process.’ A good example of this is the AutoBagging Tool (ABT) for fully automatic packaging of FOSB. “The airtight packaging of products for transport to a processing plant is a complex process and subject to the strictest criteria. cts has been able to fully automate this packaging process,” explains Alfred Pammer. The system offers a considerable increase in quality and safety during packaging, as well as a significant reduction in the workload for employees. The packaging machine, the test chamber, the robots and all other components are located in a complete cell. This has a conveyor belt for the unpackaged bundles and a conveyor belt for the packaged products. Extensive optical quality inspections, labeling (including checking the print) and folding/gluing the bags are all carried out in the ABT.

New standards in automation and the electronics industry

With the cts “Smart Factory”, the company is also setting new standards in the field of automation in the electronics industry. “Starting with incoming goods, where the complete reel is recorded and stored in the Gigaflex Storage Center, to buffering the PCB magazines in the cts Smart Warehouse and Mini Smart Warehouse, cts also offers solutions beyond this,” reports Philipp Eberherr, responsible for intralogistics solutions at cts, and adds: “We are experts in smart intralogistics and support our customers as a reliable partner in the transformation to the smart factory.”

With the storage solutions Gigaflex Reel Storage, cts Smart Warehouse and Mini Smart Warehouse, cts offers an intelligent, modular and highly effective option for storing component reels and PCB magazines. By significantly reducing shop floor occupancy, they save valuable space in the production area. The customized mini-buffer solutions (cts transfer stations) reliably compensate for minor asynchronies in the production process.

Alfred Pammer: “With the automatic supply of warehouse solutions and systems using AMRs of different sizes and load capacities, material flow can be optimized. In addition, this makes the process more flexible and reliable and enables traceability.”

The use of different AMRs, sometimes from multiple manufacturers, is easily possible with the CTs middleware sloXis®. sloXis® combines all elements of a modern industrial plant: starting with the AMRs of different manufacturers with different functionalities, to small buffers and the smart warehouse. The software forms the central interface to the MES/ERP. There is nothing standing in the way of converting electronics production into a smart factory!

Extensive experience in the pharmaceutical industry

Since its foundation, cts GmbH has been active in the pharmaceutical industry and has extensive experience in the process automation of the industry. “Pharmaceutical and biotechnological production plants are faced with the challenge of having to react ever faster and more flexibly to product and process changes. With its modular proXcab system, cts has developed a customized yet flexible solution for control, regulation and GMP-compliant recording,” reports Peter Sommerauer from the technical sales team proudly. At the same time, cts has also entered the field of radiopharmaceuticals, in addition to the production of pharmaceutical active ingredients. The production of individually dosable radioactive medications requires a highly complex manufacturing process. The system developed by CTS was not only designed, developed, built, validated and installed with automation in mind, but also with the process technology.

Everything from a single source offers added value for customers

“Everything from a single source. That's what characterizes CTS and offers significant added value for our customers. The mix of many years of experience, flexibility, short decision-making paths and creativity makes us strong,” says Johann Gehringer, Managing Director of CTS GmbH. ”In our diverse teams, young and experienced employees can learn and benefit from each other. This is how we drive innovative projects forward and ensure the expansion of the company. We are constantly growing and are therefore always looking for motivated employees,” adds managing director Robert Schüller. (red./PR)

Source: newbusiness.at