An intralogistics solution for electronics manufacturing

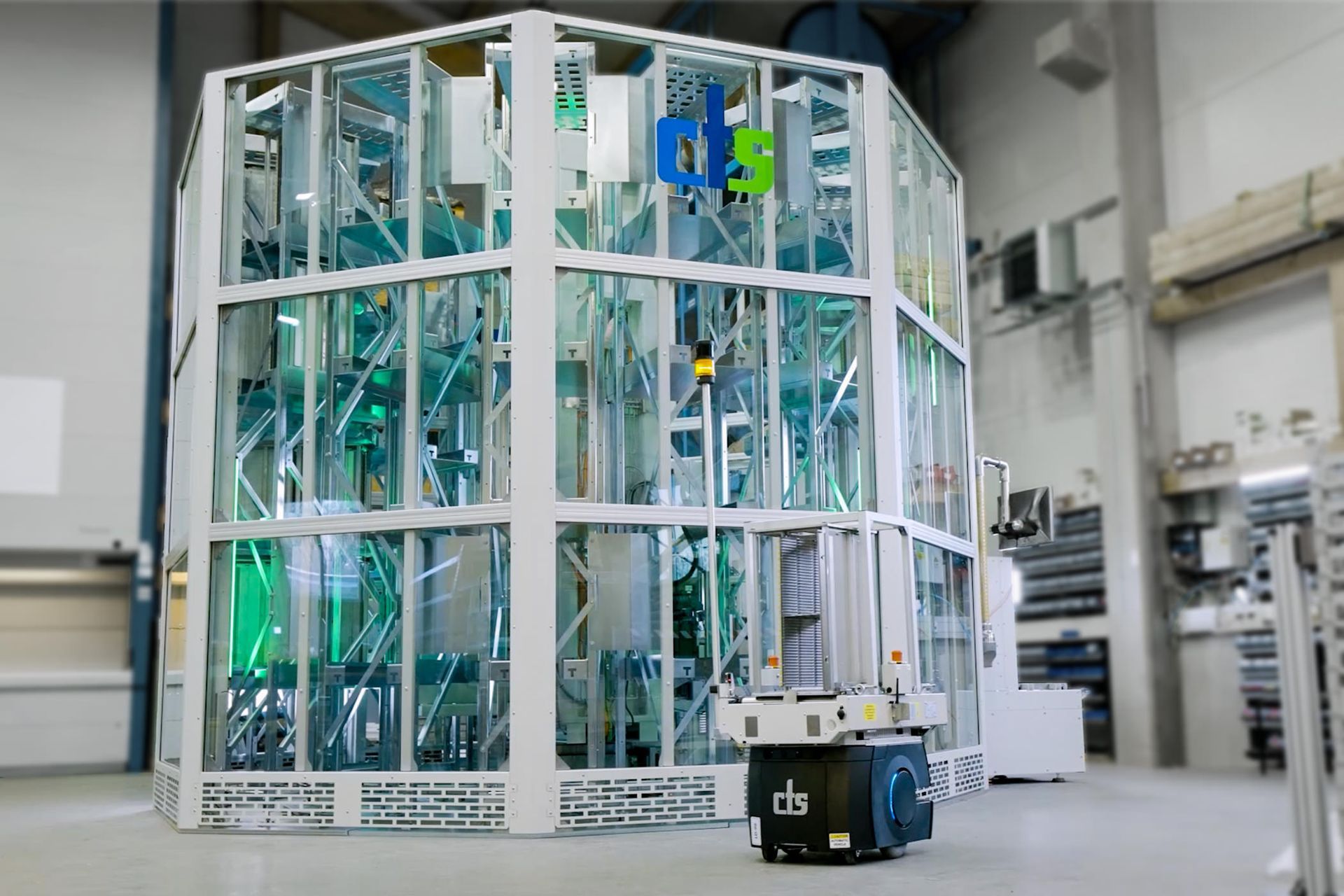

With an appearance at SMT Connect, CTS GmbH presented its contribution to the smart factory in PCB assembly. The focus was on the Mini Smart Warehouse as a production-related automatic storage option for PCBs in magazines, assemblies and components in boxes or trays.

An autonomous mobile robot (AMR), a drop point unit and a Flexlink unloader as the end point of an SMT line brought the concept to life. cts is the first intralogistics and automation specialist to offer a unified solution for automating material flows and short-term intermediate storage in production. The goals: to avoid the need for employees to walk long distances in production and to save space.

All materials in the right place at the right time

The intelligent software from cts, which can also be used to manage larger smart warehouses, is supplied with information via ERP or MES. Based on this data, the system, consisting of a smart warehouse and a self-organizing AMR fleet, ensures that all materials are available at the right place along the lines at the right time. Items that are not needed at the moment are cleared out of the way. The process was demonstrated at SMT Connect using PCB magazines, trays and KLT boxes. Thanks to its compact design with storage areas around a central robot, it is also possible to set up the Mini Smart Warehouse in clean rooms. The SMT warehouse for component reels completes the cts Smart Warehouse portfolio.

“PCBs and components, but also consumables such as solder paste or cleaning fluids – there are many things on SMT lines that need to be stored tidily and are needed quickly at the same time. We are convinced that mixed automatic storage and delivery by an intelligent system close to production is the right way forward,” explains Alfred Pammer, VP of Sales, Marketing and Product Management at cts. “Our system is open for integration with existing software and hardware. The discussions we have had at the last two trade fairs show that our intralogistics concept pursues a very practical smart factory approach that is well received.”

Source: industrial-production.de