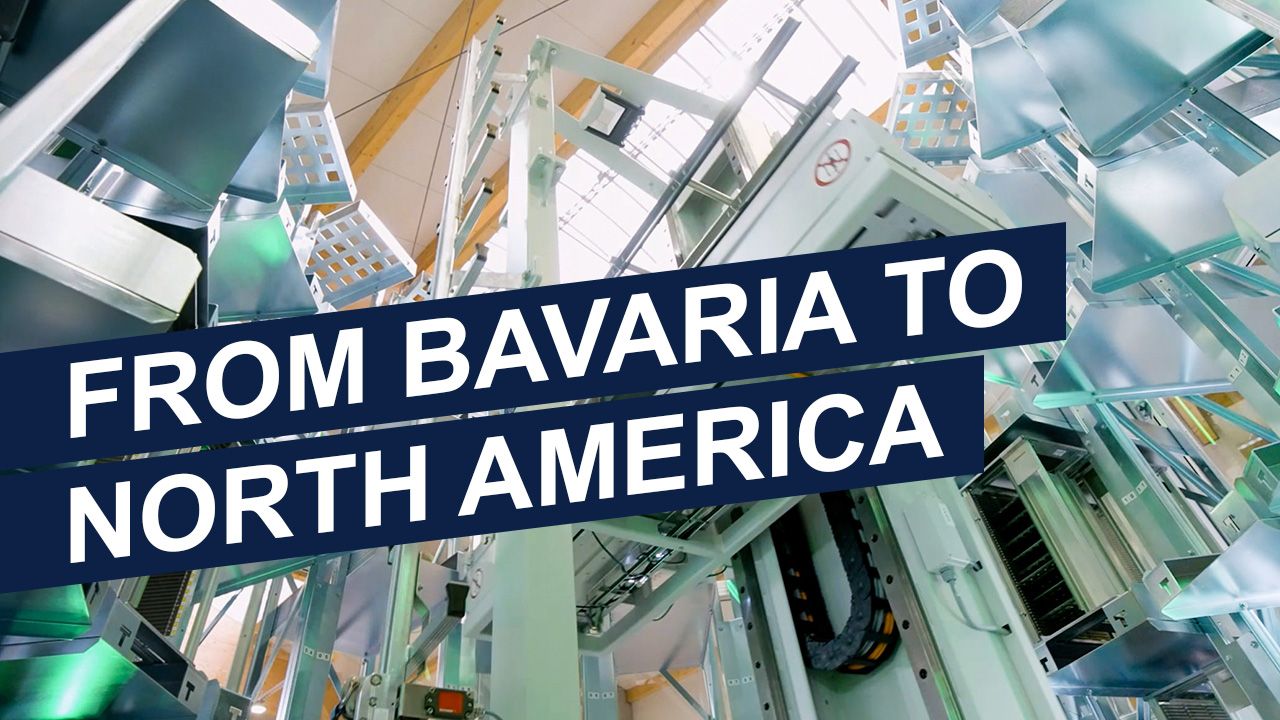

“Automation with vision” - cts and IndPro are rethinking electronics manufacturing

SMT production is considered the heart of modern electronics manufacturing - precise, fast, but increasingly complex. Global supply bottlenecks, increasing cost pressure and a growing shortage of skilled workers call for new ways of optimization. This is precisely the starting point for two companies that come from different perspectives - and yet pursue the same goal: more efficiency, more transparency, more sustainability.

We talk to Mark Juelich, CEO of

IndPro Services, and Alfred Pammer, VP Sales & Marketing at the cts Group, about a partnership that goes far beyond a technical project.

Two continents, one direction

“It all started with the realization that automation alone is no longer enough,” says Alfred Pammer, VP Sales & Marketing at CTS. “That's why we not only need good solutions, but also partners who know where they are needed. That's exactly what we do together with IndPro.”

IndPro has been active in the North American market for decades and knows first-hand the challenges of local electronics production - from the shortage of skilled labor to cost pressure and increasingly complex material logistics.

“Our aim is not to be present everywhere - but exactly where it counts.” – Alfred Pammer, CTS Group

Why now?

“The demand for electronic products is increasing, but our companies are struggling with empty labor markets, fluctuating supply chains and enormous pressure to be efficient,” explains Mark Juelich. “Many companies have state-of-the-art SMT lines - and yet material backlogs because the warehouse or replenishment cannot keep up. This is exactly where we come in with cts.”

Alfred Pammer adds: “We don't supply blueprints from Europe, but robust, scalable systems that are adapted together with IndPro - to US processes, US expectations and US speed. It's not about technology for technology's sake, but about solutions that help in the long term - today and in the future.”

“In North America, many production lines are at a standstill, not because of a lack of orders - but because of a lack of personnel. If you can't find an employee to transport materials, you need a solution that automates this job - reliably and scalably. This is exactly where the systems from cts help us.” – Mark Juelich, IndPro Services

What it will become - and what it looks like

CTS provides modular automation systems – from smart warehouses and SMT reel storage to AMR-integrated logistics – tailored to the material flow challenges of electronics manufacturing.

IndPro brings deep operational knowledge of the North American market and guides customers through selecting and implementing automation where it creates the greatest impact.

Together, we create a solution that is adaptable, investment-proof and effective.

“With IndPro, we have a partner who knows which solution is most effective at which point in the value chain - and what the market in North America really needs.”

- Alfred Pammer, CTS Group