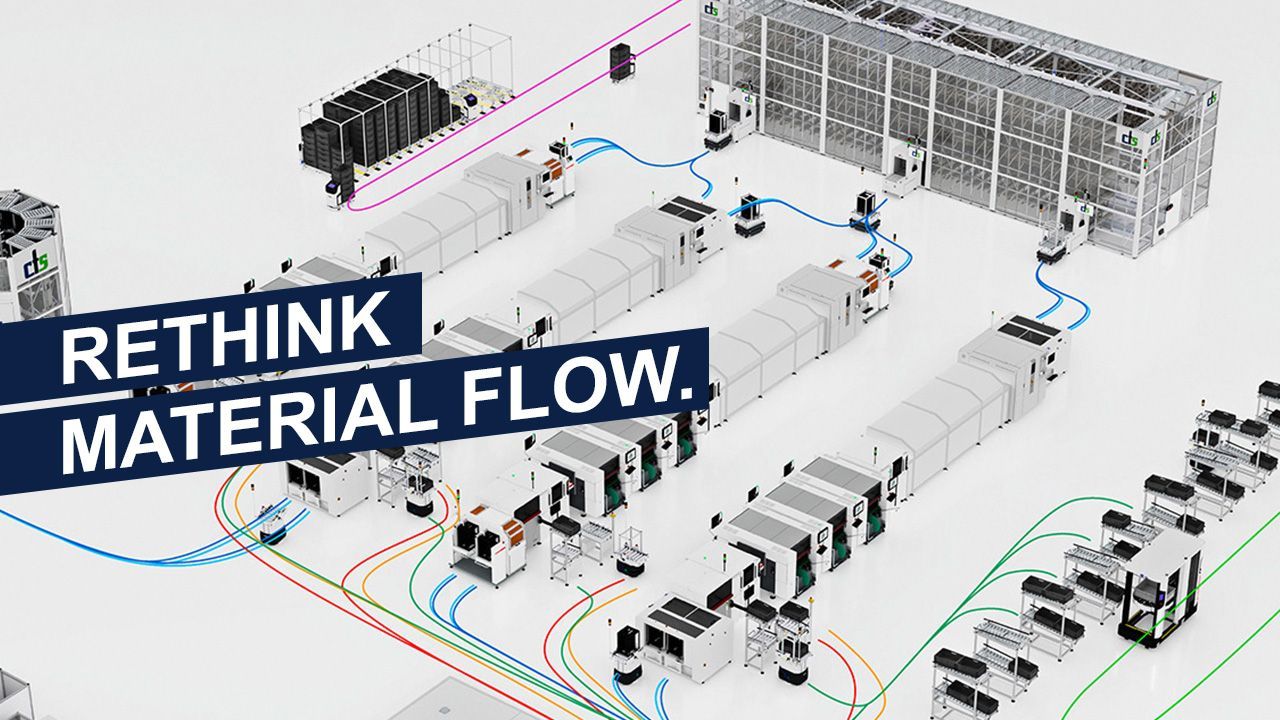

Smart manufacturing at CTS: Future proof material flow

An interview with Stefan Schmiedlechner, Business Unit Manager of Factory Automation at the cts Group.

Part 1: Traditional manufacturing reaches its limits

When we look at industrial production today, what is still too often based on outdated standards—and how is CTS changing this in Burgkirchen?

In many industrial companies, I still see highly siloed processes and manual interfaces that are error-prone and inefficient. This starts with unconnected machines and ends with inflexible production layouts. At cts, we deliberately take a different approach: we are rethinking manufacturing to make it connected, flexible, and scalable. In Burgkirchen, we develop systems in which automation, digitalization, and intelligent data flows are seamlessly integrated. This enables us to create solutions that not only meet current requirements but are also prepared for future changes.

System diversity, regulations, interfaces – why integration is often the biggest hurdle

CTS automates highly specialized manufacturing processes – from radiopharmaceuticals to SMT lines. What structural challenges do you encounter time and again?

The biggest challenge usually lies in integration: existing systems, proprietary standards, heterogeneous IT infrastructures. All of this has to be harmonized. In addition, we often have to deal with strictly regulated environments, such as in the pharmaceutical or medtech industries. This requires not only technical expertise, but also a deep understanding of the processes, standards, and requirements of the respective industry. Our strength lies in our interdisciplinary approach right from the start. Automation, software, and mechanical engineering are closely interlinked at our company.

Intelligent material flow: availability, traceability, and less friction in everyday life

The cts team often talks about “intelligent material flows” – what does that mean in reality? And how do customers notice the difference in their everyday lives?

For us, intelligent material flow means: the right product, at the right time, in the right place, with minimal friction losses. In practice, we achieve this with autonomous mobile robots (AMRs), digital traceability, and AI-supported decision-making rules. The companies we support notice the difference in significantly higher availability, shorter throughput times, and greatly improved process stability. It is no longer just about speed, but about quality, transparency, and flexibility.

Automation as a response to the shortage of skilled workers – but not a substitute for humans

Germany as a business location is under pressure: high labor costs, skills shortages, regulation. What can automation achieve - and where does it reach its limits?

Automation can help make economical manufacturing possible despite high cost structures, and it can relieve people of monotonous or dangerous tasks. It is also key to addressing the shortage of skilled workers by taking on tasks for which there are simply no workers available. But it is not a panacea. Where empathy, creativity, or social intelligence are required, humans remain irreplaceable. Automation must complement people, not replace them. Meaningful automation will secure our economic area in the long term and preserve jobs on a large scale.

Think globally, act locally – how CTS combines international standards with local strength

Cts works with international companies, for example in the semiconductor and medtech industries. How does cts in Burgkirchen manage to develop solutions that are both globally competitive and regionally rooted?

Our recipe for success is a combination of international standards and local roots. At

cts Factory Automation, we have a highly qualified team that works on an equal footing with leading companies worldwide, both technologically and organizationally. At the same time, we are strongly anchored in the region and know the needs of medium-sized customers just as well as those of global corporations. This mixture enables us to develop highly practical yet innovative solutions.