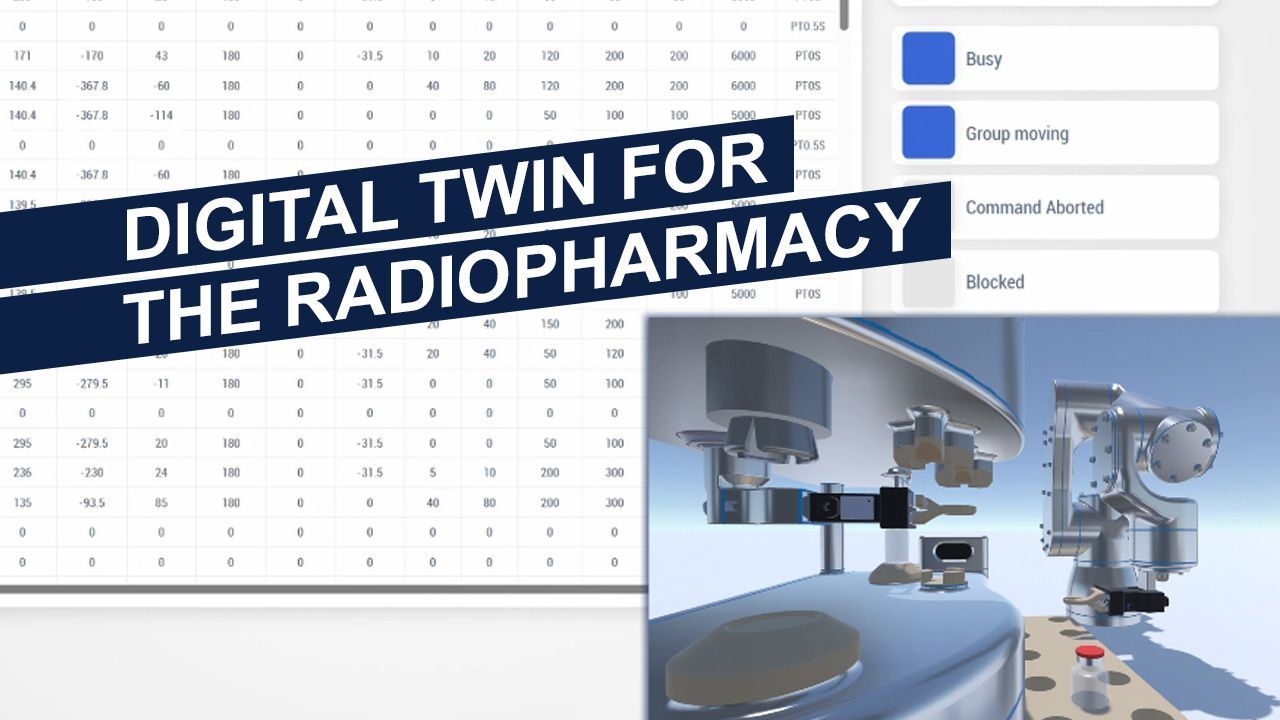

Between hot cell and digital twin: Florian's bachelor thesis at CTS

How do you automate a process that you are not even allowed to observe?

Florian wrote his bachelor's thesis at cts - on the development of a digital twin for robot-based placement in nuclear medicine. His solution brings movement to a sensitive environment in which every second counts - and every mistake can be expensive.

Who is Florian - and how did the project come about?

Florian studied electrical engineering and information technology at the TH Rosenheim. He approached CTS with a clear idea: a robot controller based on an industrial PLC - coupled with a digital twin.

"I knew that I wanted to do something of my own. When I saw the

OVD project, it was immediately clear that it would be a perfect fit."

The so-called

OVD (Open Vial Dispenser) already automates the dosing of radioactive substances. However, up to now, it has been loaded manually - and this is precisely where Florian's work began.

The challenge: automation behind lead

The special feature of nuclear medicine: simple visual inspections or manual interventions are hardly possible after the initial filling of vials in the hot cell - radiation protection and half-life times do not allow for quick interventions. A digital twin provides a remedy: complex processes can be planned, validated and tested by precisely simulating movement sequences. It also enables location-independent condition monitoring so that the entire process can be monitored at any time and from anywhere.

"You can virtually see through the hot cell with the digital twin - without exposing yourself to any danger. Seeing through the hot cell enables remote condition monitoring, which further protects the operators and makes the process safer."

The loading of the OVD system (Open Vial Dispenser) is at the heart of the solution: the OVD automates the dosing of radioactive substances into vials - a process that requires maximum precision and safety. Florian's work supplements the existing system with an automated vial feeder - thus expanding the automation potential of the entire process.

👉 You can find out more about the OVD system and its role in nuclear medicine here.

The solution: robot control with a digital twin

The aim of the work was to develop a robot controller for automated assembly - in combination with a digital twin developed in-house that represents the robot's movements in real time.

The precise representation of the kinematics was particularly important: the spatial movement of a 6-axis articulated arm robot in particular can no longer be understood intuitively. The digital twin helps with exactly this - it visualizes the movement, allowing motion sequences to be tested and checked virtually.

“If you can visually and safely understand how the robot moves in space on the screen, you can develop the control system much more quickly and safely.”

The technical implementation: PLC and simulation

Florian opted for industrial control technology - proven PLC technology instead of costly controller development. This facilitates parallel connection to other systems and opens up major advantages in terms of communication and scalability. Instead of many decentralized robot controllers, as is common in conventional robotics, several robots and adjacent production systems can be integrated centrally via a common controller.

"You work in both worlds - that's what makes the project so versatile. And by implementing it on a PLC, we have maximum integration depth in the system."

Complex data flows - cleanly solved

The biggest challenge? The data connection between the controller and the twin. While the real robot controller manages with just a few values, the digital twin must also remain reusable and scalable for larger systems.

“A cyclical exchange of over 1,000 data points within 10 milliseconds is possible without any problems” - this allows complete production lines to be mapped virtually," Florian proudly explains his development.

Responsible, but not alone

Florian was accompanied by Fabian and Daniel from the cts team - with a clear framework but plenty of freedom.

"We defined fixed goals, but I was able to work my way through them completely independently. This is a huge opportunity - you are taken seriously and really make progress."

In addition to an executable system and a convincing digital twin, one thing remains above all: real potential for the future. The technology can be scaled - for other systems, entire lines or additional functionalities such as hardware-in-the-loop simulation or condition monitoring.

"Once you have built the basic framework, the way up is open. The system is extremely free and flexible."

Personal finish - made of wood

At the end of his bachelor's thesis, Florian presented him with a personalized snack board - as a small thank you. Milled, engraved and symbolic.

"The project was something special. I wanted to leave something behind that people would remember."

This is not the end of his career at CTS - on the contrary: Florian remains loyal to the team.

"I only take positive things with me - professionally, personally and technically. That's why I'm staying. I think that says it all."